Uban areas face numerous environmental challenges because of their dense human populations and high percentage of impervious surfaces, such as rooftops and parking lots. As world population increases and urban populations expand, finding solutions to environmental issues becomes increasingly imperative to maintain viable and habitable cities.

Despite consisting largely of a built environment, urban areas still may contain diverse ecosystems, all of which provide various services that help maintain life. Trees, parks, gardens, rivers, streams and lakes offer air filtration, noise reduction, food production, micro-climate regulation, rainwater infiltration, flood control and recreation. Finding ways to improve, expand or increase the number of urban ecosystems may offer solutions to many environmental challenges.

Green, or vegetative, roof systems are one of the ways we can introduce and improve ecosystem services in urban areas. Vegetative roofs can manage storm water runoff, reduce energy use and noise, mitigate the urban heat island effect, alleviate air pollution, increase biodiversity and wildlife habitat, and add value to a building.

In 2010, in Green Roofs for Healthy Cities' annual vegetative roof industry survey of member companies, more than 710 reported projects representing 4,341,394 square feet of vegetative roof systems were installed in North America. This number is up from 2,051,736 square feet reported in 2009 and represents a significant industry growth rate. In 2010, Chicago vegetative roof space increased by more than 500,000 square feet, and in Toronto vegetative roof space increased by more than 400,000 square feet. With urban roof systems being installed or replaced annually, the potential for vegetative roof system use in the urban, built environment is an open market.

As vegetative roof systems' popularity has increased, studies have continued throughout the world to determine the optimum designs and features for each climate and bioregion, as well as how to enhance certain benefits. In 2004, a research organization, Green Roof Environmental Evaluation Network (G.R.E.E.N.), was established at Southern Illinois University Edwardsville (SIUE) to evaluate the performance of vegetative roof technologies in the Midwest.

G.R.E.E.N. currently has 12 green roof projects on the SIUE campus (including three projects associated with a new 16,000-square-foot vegetative roof system on the SIUE Student Success Center). G.R.E.E.N. researchers have a ground-level field site as well as three roof sites. Research projects have evaluated storm water runoff quantity and quality, thermal benefits, vegetative roof system installation and maintenance, and wind tunnel testing. More than 80 graduate and undergraduate students have worked on G.R.E.E.N. research projects at SIUE since 2004.

Storm water runoff

The design of a vegetative roof system significantly affects the quantity and quality of storm water runoff. Key design factors include the type of growth media, its depth, the plants selected, the type of system (built-in-place or modular) and fertilization regime. In a field study at SIUE using built-in-place vegetative roof models, Green Roof Blocks™ (modular units) and model roof decks with standard black EPDM membrane only, storm water runoff quantity and quality were monitored from September 2005 through June 2008.

The vegetative roof growth media was composed of 80 percent Arkalyte (a 6- to 9-mm expanded clay) and 20 percent composted pine bark. Results indicate a 10-cm built-in-place system is the best choice among 5-cm, 15-cm and 20-cm depths for a green roof in the Midwest in terms of storm water retention and plant coverage by sedum. This depth provides the same storm water retention and plant coverage as deeper depths but costs and weighs less, resulting in potential installation and structural savings.

A 5-cm medium depth is inadequate to provide sufficient plant growth to reach 100 percent roof coverage in a reasonable time, an important factor for visible vegetative roof systems. However, 100 percent of the sedums planted in the 5-cm growth media depth have survived during the subsequent six-year period. Sacrificing 100 percent roof coverage by using a 5-cm growth media depth or greater planting density with a 5-cm depth may be a viable option for those wishing to have a vegetative roof system on a facility that cannot accept a higher weight load.

In a second study on SIUE's Engineering Building roof, two modular systems (Green Roof Blocks and Green Paks™) were used to evaluate water loss through evapotranspiration. Both systems were 10 cm deep. Various growth media were used in a ratio of 80 percent inorganic to 20 percent composted pine bark.

In general, the bag system (Green Paks) lost more water than the tray system (Green Roof Blocks) for all media types. Typically, the growth media Arkalyte lost the least water and had the lowest sedum roof coverage while lava (natural volcanic rock) lost the most water and had the highest sedum roof coverage. The greater water loss from lava may be a result of the relatively high percentage of plant coverage and its porous surface. The porosity may allow water to be more readily available to the plants, which results in greater coverage, and may enhance evaporative losses from exposed media.

Runoff quality nutrient analyses from our ground-level field study indicated the concentration of nitrate in the runoff from the model built-in-place vegetative roof systems of various depths ranged from less than the runoff from a control roof to about 17 times greater during a 15-month period, indicating vegetative roof systems can affect water nutrient quality.

Although greater medium depths appeared to reduce nitrate concentration, their greater roof-loading weight must be considered. Vegetative roof systems appear to slightly reduce the pH of runoff compared with a typical EPDM roof, and it appears plants have more effect on pH reduction than the growth media. A laboratory pot experiment of various growth media used in a ratio of 80 percent inorganic to 20 percent composted pine bark showed total suspended solids and turbidity in vegetative roof runoff are generally low except in the first flush (the first time a substrate is wetted) from unvegetated growth media. This result has implications for establishment periods of vegetative roof systems.

Vegetative roof systems are an important tool to ad-dress storm water runoff quantity, particularly in urban areas. Questions remain regarding their effect on the runoff's quality. It is clear the design of a vegetative roof system (type of system, growth media depth, type of growth media, plant choice, etc.) is critical to the roof system's ultimate performance and that the performance will change as plant coverage increases and growth media weathers. A roof system's desired performance must be balanced with the site's design constraints, such as load limits and aesthetic requirements.

Roof runoff quality

In an urban environment, roof runoff can contain pollutants such as pesticides, hydrocarbons and heavy metals. These pollutants may originate from the roofing materials, gutters or other building components. Rain, snowfall and dry deposition can be other sources of pollutants in roof runoff.

Because vegetative roof systems retain storm water, you may assume pollutants also would be retained. This is not always the case. Recent work by our research group and others has shown some materials intended for use in vegetative roof systems could release heavy metal pollutants into the environment.

There are a variety of media that have been considered as substrates for vegetative roof systems. Some substrates are used in their natural form (such as gravel and lava rock). More commonly, substrates for vegetative roof systems are natural materials that either are blended with other materials or modified to alter their characteristics (such as diatomaceous earth, expanded clays or shale). Waste materials, byproducts from industry and some recycled materials (such as coal bottom ash, blown glassand crushed brick) also are proposed substrates. The chemical composition of these potential substrates often varies, is proprietary or simply not available. A lack of information makes it difficult to determine whether a substrate would be a source of pollutants without testing it for the presence of heavy metals.

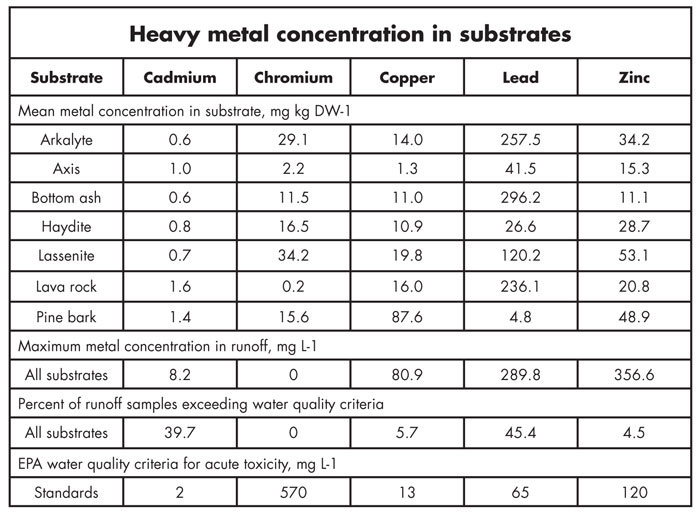

We tested several substrates to determine which might pollute the environment with heavy metals if used in a vegetative roof system (see Figure 1). The concentrations of most other elements was no different from that observed in soil or municipal sewage sludge, so there would appear to be no risk that the substrates would pollute the environment with metals such as copper or cadmium. In contrast, the concentrations of lead in Arkalyte, bottom ash and lava rock were unexpectedly high, indicating that if these substrates were used in vegetative roof systems, they could pollute the runoff with lead. Batches of these substrates intended for use in vegetative roof systems might require pre-screening to determine their lead content and lead leachability. Such testing would help ensure only material with low to no lead content would be installed on a vegetative roof.

Simulated runoff tests also were performed with these substrates to provide a more realistic assessment of whether these substrates might cause heavy metal pollution. The metal concentrations in the leachate were compared with Environmental Protection Agency (EPA) regulatory limits as an estimate of the potential environmental impact the runoff might have in the urban environment. The only two elements that were judged to be potentially problematic were cadmium and lead because 40 to 45 percent of the runoff samples had concentrations that exceeded the regulatory limit. The simulated runoff tests were, therefore, more effective in estimating whether a substrate would be a source of heavy metal pollution.

Our runoff tests also investigated how Sedum hybridum plants influenced the release of metal pollution into the runoff. For cadmium, the plants caused a greater release of this metal over time, which would translate into greater pollution in the urban environment. In contrast, the plants seemed to reduce the amount of lead pollution that might be released. The specific influence of sedum or other plant species on the release and capture of metals by vegetative roof systems is not fully understood but needs to be considered to prevent pollution in the urban environment.

During our runoff tests, copper showed a first flush behavior from some substrates, meaning copper was found in the runoff only the first time vegetative roof substrates were wetted but not again. Substrates that show this pattern of metal release or release no metals at all obviously would be the best for the urban environment. Substrates that consistently release heavy metals would cause urban environmental pollution.

To determine which way these substrates behaved, we tested runoff collected from simulated vegetative roof systems that had been outside under natural conditions for 22 months. Several elements, including cadmium and lead, were found in the runoff from Arkalyte substrate elements even after two years. The concentrations of these elements exceeded EPA regulatory limits on one or more occasions, demonstrating this substrate might be a long-term source of heavy metal pollution. However, we also found the concentration of metals in the runoff was affected by the substrate's dryness and amount of rainfall in the area.

Figure 1: Concentration of heavy metals in seven potential vegetative roof substrates and a comparison of the maximum metal concentration observed. The percentage of samples that had leachate concentrations that exceeded the EPA water quality standards are indicated.

For example, during nine months of sampling, we collected larger amounts of leachate with progressively higher concentrations of lead and zinc. This showed weather and climate can make the heavy metal pollution from vegetative roof systems even worse.

Several observations made in the field study suggested heavy metals in the runoff may have come from the vegetative roof system structure (either the materials that comprise the modular system or components of the built-in-place system) rather than the substrate that filled each vegetative roof.

For instance, the pine bark used as an organic amendment in these vegetative roof systems had a high concentration of copper, higher than all the substrates tested, making it one source of copper pollution. We also obtained other evidence that the structural components (e.g., wood, metal framing, drainage layer) used to construct the vegetative roof systems released heavy metal pollution.

Our results demonstrate that any of the components of a vegetative roof system can potentially cause heavy metal pollution. The best way to ensure heavy metal pollution would not occur would be to test the materials as we did.

Thermal performance

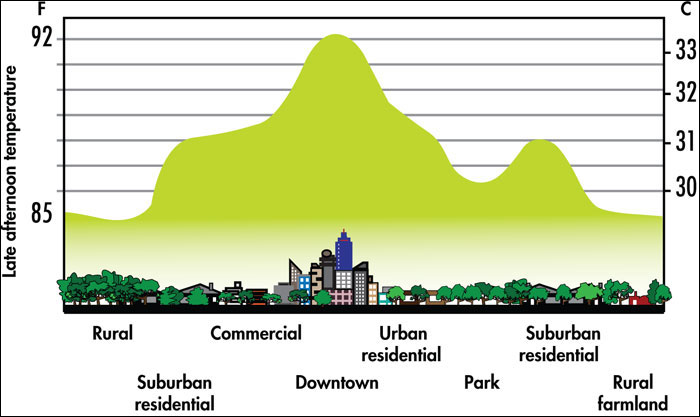

Greening the building envelope is considered to deliver several thermal benefits, such as reducing heating and cooling energy costs and decreasing the heat island effect in highly populated cities. Figure 2 illustrates the change in ambient temperature caused by the heat island effect in urban and rural areas.

Figure 2: Temperature variation caused by the heat island effect

G.R.E.E.N. theoretically and experimentally studies vegetative roof systems' energy saving benefits. For the heat transfer analysis, the plant canopy and growth medium regions can be combined to form a single do-main. An energy balance can be defined between the plant canopy-growth medium coupling and remaining roof layers. This analysis involves radiative and convective heat transfer to and from the vegetation's upper surface and conduction through the coupled system and the roof system layers below, such as the roof membrane, insulation and structural materials of the roof deck and building.

By obtaining varying daily outside temperatures, irradiation values and convective heat transfer coefficient, heat fluxes through different roof systems can be computed and compared for energy analysis.

On the experimental side, G.R.E.E.N. also studies thermal performance of different vegetation and growth media types. Some examples of the aggregate materials used in vegetative roof system growth media include lava, pumice, Haydite and Arkalyte. Some common plant types, which can be seen in Figure 3, are Sedum kamtchaticum, Sedum spurium and Sedum sexangulare.

Figure 3: Common plant types used with vegetative roof systems

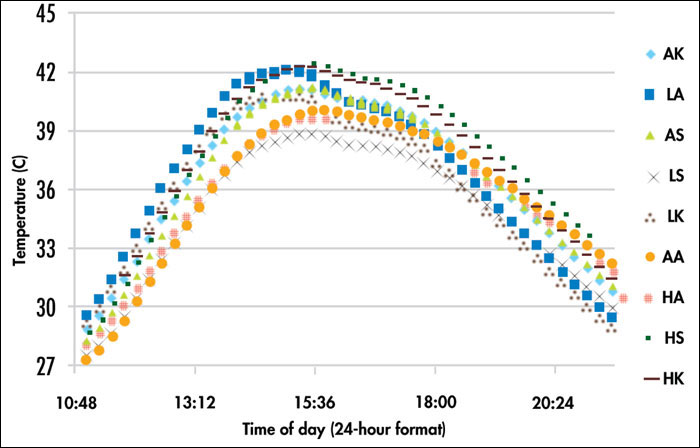

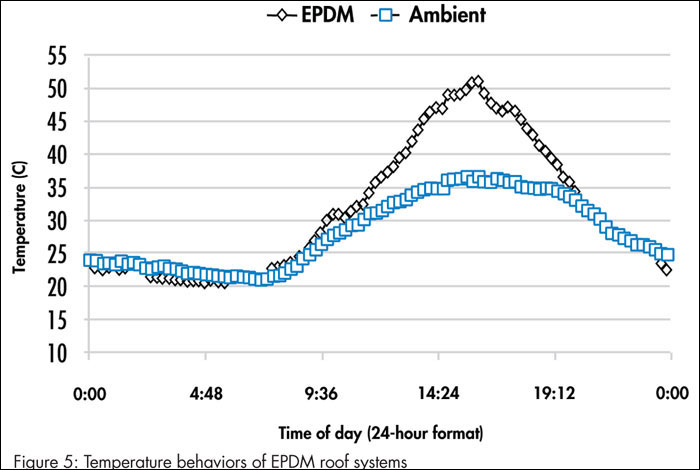

Rooftop temperature readings with different plant-growth medium coupling combinations for a selected day are provided in Figure 4. In the figure, the first letter of the vegetative roof system sample code represents the type of growth medium (A=Arkalyte, L=lava, H=Haydite). The second letter denotes the type of sedum used (K=Sedum kamtchaticum, A=Sedum sexangulare, S=Sedum spurium). These data were collected on a day when the ambient air and reference EPDM (nonreflective black) membrane temperatures were as shown in Figure 5.

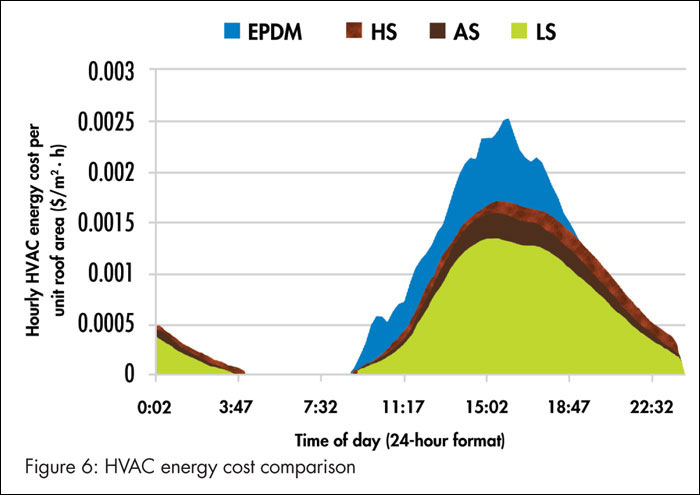

As can be observed in the plots, even the vegetative roof system sample with the lowest thermal insulative performance yields a rooftop temperature that is about 9 degrees Celsius lower than that of the EPDM roof membrane. This correlates to a significant amount of energy savings during air-conditioning seasons. Figure 6 demonstrates the hourly HVAC energy cost per unit roof area for selected vegetative roof system samples versus the EPDM roof. Energy unit price was considered as 8 cents per kilowatt hour, which is typical for the Midwest.

Figure 4: Temperature behaviors of vegetative roof systems

Wind uplift

Wind uplift of vegetative roof system components and systems has been a topic of considerable debate recently. There are ongoing efforts to develop a wind standard and wind design guidelines for vegetative roof systems. However, other than some anecdotal evidence in the U.S. of a few vegetative roof systems that have survived significant wind events, little scientific testing has been presented or published that would steer development of standards or guidelines.

Figure 5: Temperature behaviors of EPDM roof systems

We conducted an initial, systematic evaluation of wind uplift of vegetative roof system components in a recirculating wind tunnel. The project's intent was to subject vegetative roof system components to a variety of wind-uplift conditions and address three primary hypotheses to provide guidance for standard development and further product testing and evaluation.

The three primary research hypotheses were: Four inches of fully vegetated growth media can sustain two-minute wind gusts greater than 90 mph; there is a minimum level of vegetation required to bind the growth media to resist scour during two-minute wind gusts greater than 90 mph; and there are surface treatments that are effective in minimizing scour at various wind speeds.

Working with NRCA's Associate Executive Director of Technical Services Mark Graham and Kelly Luckett, president of Green Roof Blocks, St. Louis, the team at SIUE designed a series of wind tunnel research experiments to evaluate the three hypotheses. Testing was conducted on June 13, 2009, and Aug. 9, 2009. In all, 21 model tests were conducted as part of our wind tunnel research.

Figure 6: HVAC energy cost comparison

At the conclusion of our tests, all fully vegetated modules reached wind speeds of 120 mph for five minutes in the wind tunnel with no displacement of growth media. We also determined there is a minimum level of vegetation required to bind the green roof growth media. In all tests with partially vegetated modules (less than 100 percent roof surface coverage by vegetation, modules vegetated before testing), scouring of growth media occurred after reaching wind speeds of 75 mph. In tests using only growth media (no vegetative roof coverage), scour occurred at wind speeds as low as 30 mph. Therefore, 100 percent vegetation coverage or a binding agent is necessary to bind the growth media to prevent scour at wind speeds above 75 mph.

In addition, two of the four binding agents evaluated in this experiment prevented wind scour of growth media. No wind scour was observed at 140 mph when a commercial liquid binding agent was applied 48 hours before testing to a module containing only growth media. In addition, no wind scour was observed at 140 mph when a commercial liquid binding agent was applied to a partially vegetated module 48 hours before testing. Further, no wind scour was observed with speeds above 120 mph when 100 percent natural burlap was used as a surface treatment.

The data reported here is just the beginning of evaluative testing necessary for the manufacture and installation of vegetative roof systems. Further testing must include individual components and total systems. Since we first reported the results of our wind tunnel experimentation, a wind standard that provides a method of designing wind uplift resistance of vegetative roof systems was developed and published (ANSI/SPRI RP-14 2010). In the new design standard, guidelines are set forth that detail testing at different building heights, roof slopes, exposure categories, roof systems, perimeter areas, corner areas, roof field, etc. More testing will be required by green roof system manufacturers to conform to the new wind standard.

Future work

Much of our work has helped increase the understanding of the performance of vegetative roof systems and their components, yet we still have more work to do. Our replicated research experiments, as good science does, have led us to many more questions. With the improvement in technology and new innovative vegetative roof systems, there also are more questions about performance and standards.

During the past year, we have begun evaluating vegetative roof systems designed for residential roofs and the biodiversity (plants and insects) that results from the installation of green infrastructure on the rooftop. For more information about our research, go to www.green-siue.com.

Bill Retzlaff, Ph.D., is associate dean of SIUE's College of Arts and Sciences; Stephen Ebbs, Ph.D., is associate professor and assistant chair for Southern Illinois University Carbondale's department of plant biology; Susan Morgan, Ph.D., is chair of and professor for SIUE's department of civil engineering; and Serdar Celik, Ph.D., is assistant professor for SIUE's department of mechanical engineering.