Sustainable and green building standards and codes rapidly are being developed at national and state levels. The U.S. Green Building Council recently released LEED 3.0; ASHRAE is developing 189.1,"Standard for the Design of High-Performance Green Buildings Except Low-Rise Residential Buildings"; the International Code Council (ICC) and National Association of Home Builders promulgated the National Green Building Standard for residential buildings; the ICC has begun developing a green building code for commercial buildings; and various cities and states have developed their own green building codes.

The development and implementation of these codes, which follow sustainable and green building trends in general, are driving the construction industry's product development and research. In many instances, new standards and information regarding low-slope roof system performance are needed to address the requirements being implemented. SPRI, an association representing single-ply roof membrane manufacturers and component suppliers, has taken a leadership role in addressing those needs.

Vegetative roof systems

Vegetative roof systems are gaining popularity in North America because of environmental benefits associated with them, such as:

- Initial retention and slow release of storm water

- Reduction of heat island effects

- Improved energy performance because of the presence of growth media providing thermal mass and plants, which also reduce heat energy entering a building through evapotranspiration

- Improved aesthetics and workplace environment

Many of the previously mentioned codes and rating systems provide points toward achieving sustainable building recognition if a vegetative roof system is installed. To support using these environmentally friendly roof systems, the roofing industry has begun developing consensus standards to address vegetative roof system performance when such systems are exposed to fire and wind conditions.

During the 2006-07 International Building Code (IBC) code change cycle, a proposal was presented and adopted requiring evaluation of vegetative roof systems for wind- and fire-resistance properties. Currently available evaluation procedures could not be used because of the vast array of variables that could be present with vegetative roof systems, such as plant material, the soil's water content and spacing of the plant material.

Recognizing current procedures could not be used, SPRI and Green Roofs for Healthy Cities (GRHC) decided to develop standard design guidelines for vegetative roof systems regarding wind uplift and fire resistance. Numerous manufacturers and consultants involved with the vegetative roofing industry are playing a vital role in these standards' development. NRCA has been part of the American National Standards Institute (ANSI) balloting process.

SPRI and GRHC also have begun developing a consensus standard to evaluate a roofing material's ability to resist normal root or rhizome (a horizontal plant stem that usually is found underground, often sending out roots and shoots from its nodes) penetration through a root protection barrier or waterproofing layer. All these standards are being developed through the ANSI consensus standard development process; they currently are incomplete.

Wind and fire

Because a vegetative roof assembly's top covering is loose-laid, it behaves similarly to a ballasted roof assembly. The requirements of the wind-uplift standard for vegetative roof systems are based on data developed during large-scale wind tunnel testing. These tests initially were conducted to provide data to support the proper design of gravel and paver ballasted single-ply roof systems. The wind tunnel tests led to understanding the effects of variables such as wind speed, ballast particle size, ballast weight, building height, parapet height and the location at which wind impacts a building.

Industry practices that have demonstrated acceptable wind-load resistance levels for more than 40 years—primarily in Europe—also were used to develop this standard.

The standard's users will select one of three vegetative roof options based on design wind speed, exposure conditions, building height, parapet height, individual building characteristics such as large openings in the wall, and rooftop projections.

The wind-uplift standard will be sent out for its fourth ballot.

Additionally, vegetative roof systems' fire resistance is an issue. Vegetative roof systems contain combustible plant materials; however, fire produced when these materials burn does not contain a large amount of energy. When properly designed, vegetative roof systems have demonstrated excellent fire resistance. Proper design is achieved by providing setbacks from combustible surfaces. The proposed standard offers design methods for providing external fire resistance for vegetative roof systems.

Two key design requirements contained in the fire-resistance standard are:

- Requirements for large roof areas: A firebreak consisting of a minimum 6-foot-wide class A-rated (per ASTM E108/UL 790, "Standard Test Methods for Fire Tests of Roof Coverings") roof system must be used to partition the roof area into sections not exceeding 15,625 square feet with each section having no dimension greater than 125 feet. One or more fire hydrants should be provided for a minimum 6-foot-wide continuous border.

- Requirements for rooftop structures and penetrations: If the vegetative roof system abuts combustible vertical surfaces, a class A-rated (per ASTM E108/UL 790) roof system must be achieved for a minimum 6-foot-wide continuous border placed around rooftop structures and all rooftop equipment.

The fire-resistance standard currently is out for its fourth ballot.

Vegetative roof system maintenance is important to provide long-term resistance to wind and fire exposure. For this reason, the proposed wind- and fire-resistance standards contain requirements to keep vegetative roof plants healthy and minimize dry foliage. Building owners need to be aware of this responsibility.

Code change proposals have been submitted for the 2009-10 IBC cycle to include these wind- and fire-resistance standards in the IBC to provide needed guidance for vegetative roof system installation. It is hoped a standard will be developed that will receive sufficient support to complete the ANSI process within the next two ballots; the process will take until the end of 2009.

Proposals also have been submitted to include maintenance requirements for vegetative roof systems in the International Property Maintenance Code.

Root barrier standard

SPRI and GRHC have begun developing a consensus standard to evaluate a roofing material's ability to resist normal root or rhizome penetration through a root protection barrier or waterproofing layer. This standard's test is based on the FLL Guideline, "Procedure for investigating resistance to root penetration at green roof sites." The FLL procedure was developed in Germany and is based on findings and testing experience of evaluating various materials during a number of years. This test is intended to build on evaluations and field experience and provide an equivalent evaluation protocol for North American test sites.

Thermal performance

One of the desirable performance characteristics of a vegetative roof system is its ability to enhance a roof system's thermal performance. But how much does thermal performance improve when a vegetative roof system is installed?

To help answer this particular question, those developing energy codes and in the design community raised some other questions, including:

- What is the effect of the growth media's thickness?

- How does moisture content affect thermal performance?

- Does the presence of live plants affect thermal performance?

- How does the application method affect thermal performance (for example, trays versus growth media)?

This information can help provide guidance when developing energy codes and properly crediting vegetative roof systems' contributions. To fulfill this need, SPRI and the U.S. Department of Energy funded a research program conducted at Oak Ridge National Laboratory (ORNL), Oak Ridge, Tenn. Specifically, the program evaluated the effects on thermal performance of the following variables:

- Growth media thickness. Two thicknesses of growth media were evaluated: 4 1/2-inch-thick to represent an extensive vegetative roof system and 8 1/2-inch-thick to represent an intensive system.

- The growth media's moisture content. Moisture content was identified as a critical variable that could affect a vegetative roof system's thermal performance. For this reason, the test was instrumented to record moisture content and heat flow simultaneously. Moisture contents ranging from near saturation to less than 5 percent by volume were measured during the test period.

- Presence of plants. Systems were tested with and without plants to determine how plants affect vegetative roof systems' thermal performance.

- Vegetative trays versus growth media in direct contact with the roof system. All systems contained a protection layer and drainage layer.

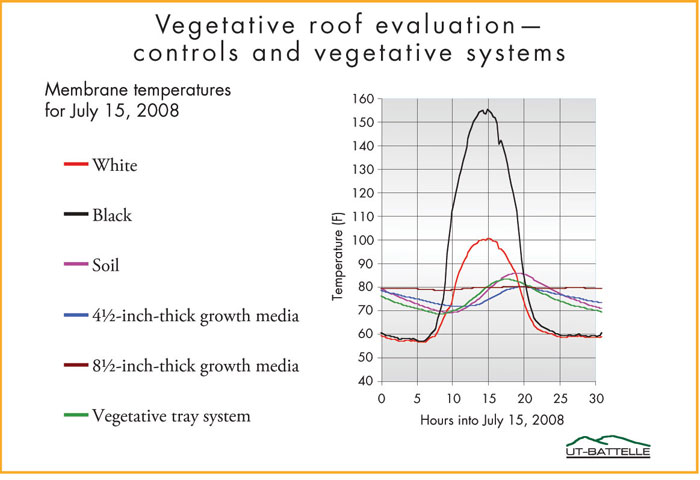

Vegetative roof systems' thermal performances were compared with the thermal performances of white and black single-ply membrane roof systems. All systems used 1 1/2-inch-thick wood fiberboard as insulation. Growth media moisture content, membrane temperatures and system heat fluxes were recorded every 15 minutes for one year so ambient temperatures' influence could be determined. The data will be used to develop predictive models that will help determine vegetative roof systems' thermal performances in various climate zones. Photo 1 shows the test sections' installation at ORNL.

The report for this study currently is being finalized, but an example of the data obtained is shown in Figure 1. It is clear the vegetative roof system improved the roof system's thermal performance. It also was determined that thicker growth media and the presence of plants had a positive effect on the roof system's thermal performance. This was determined by directly comparing the systems' thermal performances.

So, for example, the thermal performance of the vegetative roof system was compared to the bare roof surfaces used during the study. Vegetative roof systems' thermal performances with and without plants also were compared during the study. The finished report will be published on SPRI's Web Site, www.spri.org.

Figure 1: Data obtained by Oak Ridge National Laboratory, Oak Ridge, Tenn., when comparing thermal performances of vegetative roof systems with white and black single-ply membrane roof systems

Exploring corrosion

Effective in January 2004, the U.S. Environmental Protection Agency mandated a change in lumber and timber preservative materials primarily because of health and environmental concerns. Although copper chrome arsenate (CCA)—the preservative used before January 2004—still could be used in some applications, it generally was not cost-effective for manufacturers to continue using it. In most cases, CCA was replaced with preservatives with higher copper contents commonly referred to as alkaline copper quartenary (ACQ). It was determined that in some applications, ACQ preservative use increased the potential for corrosion of metal components in direct contact with the treated lumber.

Roofing industry members expressed concern that wood nailers treated with ACQ preservatives could corrode metal fasteners used to keep roof edge systems in place on low-slope roof systems. Investigations of low-slope roof systems after hurricane wind events clearly have demonstrated that, in many instances, roof system failure began at the edge and propagated across the entire roof. Because we know that in the majority of cases roof edge failure is the first thing that happens during a high wind event, we wanted to explore corrosion of metal fasteners.

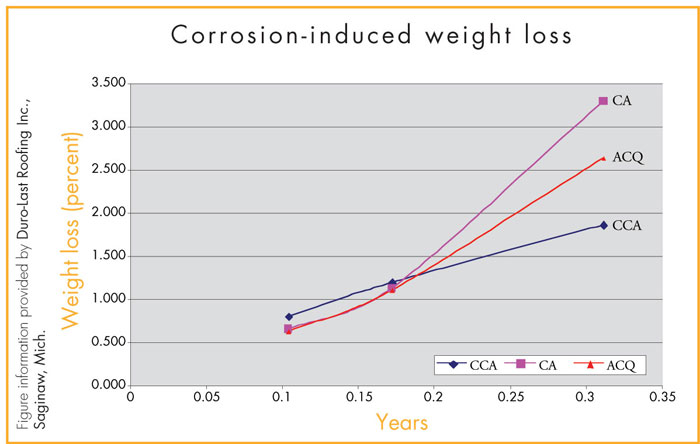

Figure 2: A summary of the corrosion-induced weight loss of black e-coated carbon steel fasteners when embedded in wood blocks treated with copper chrome arsenate (CCA), alkaline copper quartenary (ACQ) and copper azole (CA) preservatives

To address this concern, SPRI, with funding support from the RCI Foundation and National Research Foundation, initiated a project to evaluate the potential for metal fastener corrosion when metal fasteners contact preservative-treated wood in low-slope roof system installations.

As part of this study, data were collected in various laboratories that identify critical variables that cause corrosion of metal fasteners in contact with wood using various preservative types, as well as theories established as to why this reaction occurs. Figure 2 provides a summary of one set of data obtained from this study. Four fastener types were evaluated in contact with five wood treatments; untreated lumber acted as a control. The graph summarizes the corrosion-induced weight loss of one fastener type—black e-coated carbon steel—when embedded in wood blocks treated with three wood preservatives—CCA, ACQ and copper azole preservatives. The wood blocks continuously were exposed at 120 F and 90 percent RH during this portion of the study.

In addition, buildings in the U.S.' northeast, southeast and northwest regions were instrumented to determine the temperature and humidity conditions that occur in the nailer area. In this field study, a water-soaked wood nailer was installed to represent the worst-case scenario. The drying rate of the water-soaked wood nailer also was determined. Photo 2 shows the test nailer and monitoring equipment being installed at the northeast location.

The primary conclusion from this study was that the critical temperature and humidity conditions necessary to initiate corrosion of metal in contact with treated lumber were not reached. The laboratory analysis demonstrated that for corrosion of metal in contact with treated lumber to occur, a combination of relatively high temperature and, particularly, humidity must be maintained. The field studies showed these conditions do not exist in a wood nailer as used in low-slope roof systems. This is true even when the wood nailer is saturated with water when installed.

Looking ahead

Sustainable and green building requirements rapidly are being promulgated and implemented in the roofing industry. In some instances, standards and performance data are needed to support these requirements. In the single-ply roofing industry, SPRI—with the support of other roofing industry parties—continues to work to develop standards and conduct research that will provide valuable information for the roofing industry's future.

SPRI is considering working with the roofing industry to conduct wind and fire tests on vegetative roof systems to provide additional performance data.

It also has initiated an emerging technologies task force and is soliciting members. Examples of issues the task force will address include using the roof as a platform for photovoltaics, as well as how to do so while keeping the roof watertight.

Finally, SPRI has initiated a task force that will investigate membrane color's effect on building energy performance and moisture content of the roof assembly in various climate zones.

Mike Ennis is a technical director for SPRI.