The NRCA Roofing and Waterproofing Manual, Fifth Edition, contains reroofing guidelines for steep- and low-slope roofing. The August 2004 issue of Professional Roofing featured an article that discussed the steep-slope text of the manual (see "Steep-slope reroofing considerations," page 28). This article focuses on the low-slope reroofing section.

Background

NRCA defines low-slope roof systems as a category of roofing that includes weatherproof types of roof systems installed with slopes less than or equal to 3-in-12 (14 degrees). Because each roof system is unique, it is not practical to address every condition that may be encountered during a reroofing project. The manual's reroofing section provides information applicable to many conditions commonly encountered during a reroofing project.

Low-slope roof assemblies typically are composed of a roof membrane, roof insulation, vapor retarder—when built in—and roof deck. Together, a roof membrane—including surfacing, insulation and vapor retarder—are considered a roof system. A roof system plus a roof deck are considered a roof assembly.

Other terms and definitions used in this article and the reroofing section can be found in "Terms to know," page 43.

When maintenance or repair no longer can effectively prevent leakage or extend useful roof system service life, consideration must be given to roof system re-cover or replacement when one or more of the following occurs:

- Repair expenditures become excessive

- Leakage becomes intolerable

- Damage is occurring to the structural components

- Damage is occurring to building interior finishes and/or contents

Replacement triggers

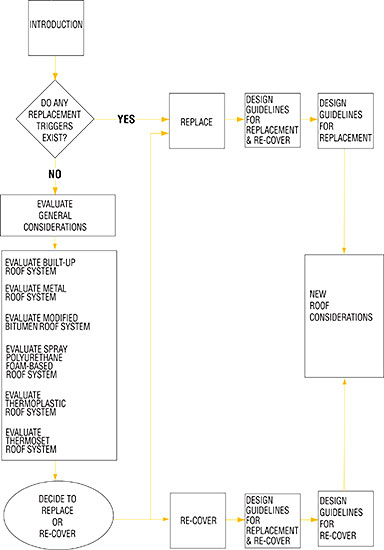

Once it is determined a roof system has little or no useful service life, the decision to re-cover or replace the roof system needs to be made. The manual's reroofing section offers guidelines for determining whether to replace or re-cover. The figure on page 42 contains a flow chart that illustrates the decision-making process.

There are a number of factors that can preclude installation of a re-cover roof system. These are called replacement triggers, and determining replacement triggers is the first step on the flow chart. If a replacement trigger exists, a roof system should be replaced. If a replacement trigger does not exist, evaluation of the existing roof assembly is recommended before the decision to replace or re-cover is made.

As a guideline, NRCA offers several replacement triggers for low-slope roof systems:

1. Building code requirements. A new roof system should comply with applicable building code requirements. If an existing roof system does not comply with current code requirements, installation of a re-cover roof system also may not meet building code requirements. For example, re-covering an existing roof system that ponds water with the addition of a separation layer—such as insulation board—and a membrane, without correcting the ponding, may not comply with positive drainage or minimum slope requirements mandated in the building codes.

Wind-uplift and fire-resistance ratings' requirements are another building-code issue to consider. Installing a roof system that cannot adequately be secured over an existing roof system may not provide required wind-uplift resistance, and adding certain types and/or thicknesses of insulation over an existing roof system may alter fire-resistance ratings.

All model building codes limit the number of layers of roof systems that can be installed on buildings. Local codes should be checked for specific requirements and limitations. For buildings with multiple layers of roof systems, NRCA recommends the removal of all existing roof layers before installation of a replacement roof system.

2. Roof system condition. An existing roof system may not be suitable for a re-cover roof system because of its surface condition. NRCA recommends a roof surface be relatively smooth and free of extensive blistering, buckles, ridges, surface contamination or corrosion.

3. Wet insulation. NRCA does not recommend installation of a re-cover roof system over existing wet insulation or other wet materials. Model building codes do not allow installation of a new roof system over existing roof systems with wet insulation. NRCA also does not recommend any configuration intended to dry out wet insulation.

4. Perimeter conditions. A building may be designed and built in such a way that the addition of a re-cover roof system and/or tapered insulation cannot be installed without major modifications to the existing structure and/or curbs and penetrations. As an example, if a base flashing height of 8 inches (200 mm) cannot be provided at through-wall flashing details, a re-cover roof system may not be possible.

5. Roof deck condition. NRCA does not recommend installation of a re-cover roof system over a damaged or deteriorated roof deck. A damaged or deteriorated roof deck should be repaired or replaced during a roof system replacement. It is important to note the degree of corrosion or deterioration visible from a deck's underside may not adequately predict the extent of roof deck degradation that may exist on the roof deck's topside.

Fastener holding capacity significantly can be reduced, as well as overall load capacity. NRCA is concerned with potential fastener-holding problems and dimensional stability where oriented strand board, other nonveneer products and fire-retardant-treated plywood are used as roof decks.

6. Vapor retarders. It may be necessary to remove an existing roof system to install a vapor retarder if there are condensation problems; a vapor retarder was needed but never installed; or there is a change in a building's use that results in an increase of interior moisture.

Ventilation, vapor retarders and dew-point conditions are interrelated. The presence of a vapor retarder and amount of insulation and ventilation affect the potential for condensation. NRCA recommends calculations be made to determine the need for and location of a vapor retarder. More information can be found in the Moisture Control section of The NRCA Roofing and Waterproofing Manual, Fifth Edition.

7. Phenolic foam insulation over steel decks. Phenolic foam insulation is a rigid, closed-cell foam product generally characterized with an orange or reddish-brown foam core. It was available as roof board insulation in the United States and Canada from about 1982-92. Although it no longer is produced in the United States and Canada, relatively large quantities remain in existing roof systems.

Phenolic foam insulation in direct contact with a steel deck and in the presence of moisture likely will cause corrosion on galvanized or painted steel decks and other roof system components, such as fasteners. Because of the possible corrosive environment at a steel roof deck/roof insulation interface, NRCA recommends phenolic foam roof insulation in direct contact with a deck be removed during replacement of steel deck assembly roof systems. Removal of the insulation allows for the inspection and repair or replacement of a steel roof deck.

8. Composite roof decks. A composite roof deck incorporates materials with different structural properties. An example is light-gauge metal roof decks and gypsum boards fastened together so the combined materials are stronger than any individual component. Caution should be taken when removing gypsum board used over a steel deck for fire resistance; lightweight insulating concrete used over a steel deck; and lightweight insulating concrete used over insulation board or gypsum board.

9. Direct-to-deck polystyrene insulation. Building codes have placed restrictions on the use of polystyrene insulation—both expanded and extruded—that is installed directly on metal decks. NRCA does not recommend installation of any re-cover roof system over an existing roof system that incorporates polystyrene insulation applied directly to a metal roof deck.

10. Nonreinforced PVC membranes. Aged, nonreinforced PVC membranes may shatter when there is a significant drop in temperature. Typically, when shattering occurs, it extends throughout the entire roof area and the roof is considered unrepairable. NRCA suggests roof systems with aged, nonreinforced PVC membranes be replaced to avoid potential failure.

However, even if no replacement triggers exist, the decision to replace or re-cover still needs to be determined.

The flow chart illustrates the decision-making process.

Replace or re-cover

A more extensive roof assembly evaluation should include the following six general considerations: observations of the roof deck's underside; attachment of existing roof system to roof deck; load considerations; insulation; site-specific considerations; and hidden conditions.

Whenever possible, observe a roof deck's underside. Certain types of construction or building use may limit or prevent the ability to make underside observations. Slope, deterioration and composition are issues to consider when making visual observations of the roof deck.

When observing a deck's underside, note the fasteners penetrating the deck. For metal decks, if fasteners are visible, the insulation is mechanically attached; however, do not confuse metal deck fasteners with insulation fasteners. If fasteners are not visible, the roof system may be loose-laid and ballasted or the insulation may be adhered to the deck with asphalt or adhesives. Lightweight or insulating concrete may be on top of the metal deck (this generally occurs over corrugated decking). Test cuts may be necessary to determine the attachment method.

For concrete decks, a roof system most likely is fully adhered or loose-laid though mechanical attachment is a possibility. It is unlikely the attachment method of a roof system will be determined by viewing the underside of a concrete roof deck.

For nailable decks, such as wood, gypsum and cementitious wood-fiber decks, it is likely a mechanically attached base sheet and/or separation layer is installed. Some roof systems may be fully adhered, spot-mopped, or fastened with toggle bolts or auger-type fasteners.

The attachment of an existing roof system to a roof deck may not comply with current model building codes. Re-cover systems may not be allowed under certain conditions or, if allowed, modifications to the existing attachment method may be necessary to comply with code requirements.

The load capacity of a roof deck and/or structure can be a factor when deciding to re-cover or replace. The design capacity of the roof structure should be a factor when considering a re-cover or heavier replacement system.

Because the type and thickness of insulation cannot be determined through visual observation, examination of construction documents and shop drawings or taking core cuts of the roof system are possible ways to obtain such information. The location of wet insulation or materials should be determined. Nondestructive moisture surveys can be beneficial in finding areas of wet insulation; however, test cuts or destructive testing should be conducted to confirm findings.

There also are important site-specific considerations to note. A roof membrane should be checked for the presence of contaminants discharged from mechanical equipment or vents. Many such substances will degrade roof membranes and surfacings and may dictate the selection of a replacement system. Remove areas of contaminated roof membranes before reroofing. Replacement of the entire roof system may be necessary if a significant portion of the roof system is contaminated.

Items such as electrical conduit and plumbing may be buried in roof insulation, concrete roof decks or lightweight insulating concrete roof decks or placed directly above and/or below metal or wood decks. Do not disrupt or damage these components.

After carefully considering the previously mentioned issues, evaluate the existing roof system to determine whether it can remain in place and review the reroofing section of NRCA's manual. The manual addresses additional issues to assess specifically related to six low-slope roof system types: built-up, polymer-modified bitumen, thermoset, thermoplastic, metal and spray polyurethane foam (SPF)-based. Issues addressed for each roof system type are roof surface condition, flashings, building-related leak sources, historical files, drainage and slope, and roof system composition.

Because each reroofing project is unique, there are no predisposed guidelines—except for the replacement triggers—to follow during the decision-making process. A decision can be made based on your experience, building owner requirements and the desired service life of a new roof system.

Reroofing guidelines

Whether the decision is to re-cover or replace, both cases have similar design guidelines and involve a multitude of issues.

One issue is regulatory requirements must be addressed. Any type of reroofing project must comply with local building codes. Most building codes address reroofing and may include requirements with regard to repair limits, minimum design slope, load considerations, parameters for re-cover vs. replacement, combustible sealed spaces, and reinstallation of materials and flashings. Building codes also may require a roof system to meet certain wind-uplift-resistance, fire-resistance, drainage and energy-code requirements.

As previously mentioned, the weight of a replacement or re-cover roof system also should be considered. Refer to the manufacturer for the specific weight of the selected roof system, and verify the roof structure capacity during a reroofing project's design.

When specifying a replacement or re-cover roof system, one goal is to meet or exceed the building owner's desire for service life of the new roof system. NRCA lists five criteria of particular importance to achieve maximum service life: eliminate or minimize ponding; limit and properly flash penetrations; replace metal accessories as needed to allow them to perform over new systems' anticipated service life; don't exceed existing design loads; and correct inadequate ventilation.

During the reroofing process, construction loads from equipment or stored materials may approach or exceed load capacity of the roof structure. Be sure to spread loads properly so significant or excessive concentrated loading does not occur.

Finally, be aware that freezer and cold-storage facilities are unique with regard to moisture drive. Because the interiors of these facilities usually are cooler and drier than the exteriors, moisture drive typically is from outside to inside. Fastener penetrations and double vapor retarders developed by a re-cover roof system may preclude a re-cover roof system as an option.

Replacement guidelines

There are three principal design considerations for the replacement of low-slope roof systems: roof deck preparation, perimeter conditions and roof penetrations. In general, roof decks should be sufficiently dry, clean, smooth and suitably prepared before installation of a replacement roof system. NRCA addresses six roof deck types that may be encountered: metal, wood, lightweight insulating concrete, cementitious wood fiber, concrete, and poured-in-place or precast gypsum. Less common structural decks and substrates include thermosetting insulating fill, structural hollow tile, lightweight fill, nailable concrete planks, composites and various proprietary materials. Each roof deck type has specific characteristics to consider; refer to the manual for further information.

After removing an existing roof system, you will need to inspect the wood blocking at the perimeter for deterioration, straightness, attachment to the substrate and fastener-holding capacity. Deteriorated, damaged or inadequately fastened blocking should be replaced. Also, you will need to assess existing perimeter flashing heights and configurations.

Inspect areas around rooftop penetrations after the removal of an existing roof system. Penetrations are common locations for moisture infiltration and deterioration of the roof deck and/or penetration material. Complete replacement of a roof system should include replacement or repair of any materials that do not have remaining service lives equivalent to the expected service life of the new roof system. A penetration's framing structure also should be inspected, repaired and adjusted as necessary.

Re-cover guidelines

The design considerations for re-cover roof systems are as follows:

- Material compatibility: A re-cover roof membrane, separation layer or insulation should be compatible with an existing roof system. There is potential for new and existing membranes to be in contact, and certain materials may be incompatible even without direct contact. Because the new roof insulation and/or separator layer will contact new and existing roof systems, they need to be compatible with both. First, choose materials compatible with the existing roof system and then choose a roof system compatible with the insulation and/or separator.

- Removal of wet insulation: Although applying a new roof membrane over an existing membrane sometimes is practical and advantageous, there is the potential for trapping moisture within the combined roof systems. Entrapped moisture may cause blisters or other problems. In the case of a mechanically attached re-cover system, wet insulation can corrode existing or new fasteners.

- Wood blocking: In cases where perimeter edge metal exists, wood blocking should be inspected for deterioration, straightness, attachment to the substrate and fastener-holding capacity. Replacement of deteriorated, damaged or inadequately fastened wood will need to be considered.

- Installation methods: There are three methods for installing re-cover roof systems: mechanically fastened, adhered, and loose-laid and ballasted. Obviously, all re-cover roof systems will add weight (dead load) to the roof assembly, especially ballasted systems. Mechanically fastened systems rely on the pull-out resistances of the fasteners to provide attachment and wind-uplift resistance. Adhered systems that are attached directly to an existing roof system rely on the existing system's attachment for wind-uplift resistance, and compatibility of the existing system and adhesive should be evaluated. Loose-laid and ballasted systems rely on the ballast's weight to provide wind-uplift resistance.

- Separation layer: NRCA suggests a separation layer be used before installation of a re-cover roof system. For example, a hot-applied re-cover built-up or modified bitumen roof system over an aggregate-surfaced built-up roof system requires use of an appropriate separation layer. A separation layer separates incompatible materials; allows differential movement between roof systems; provides a clean, dry, smooth and level surface; and/or separates a new roof system from the anomalies of an existing roof system.

- Existing system preparation: An existing roof system needs to be prepared properly before installation of a re-cover roof system. The manual contains specific guidelines for built-up,modified bitumen, metal, SPF-based, thermoplastic and thermoset membrane roof systems, including separation layer recommendations appropriate to the specific roof system being re-covered.

- Specific re-cover roof system recommendations: NRCA offers general recommendations for re-covering with built-up, modified bitumen, metal, SPF-based, thermoplastic and thermoset membrane roof systems.

New roof system guidelines

Once all considerations have been addressed and the necessary preparations and/or modifications made, a new roof system can be installed. Information regarding installation of a new roof system can be found in the appropriate section of The NRCA Roofing and Waterproofing Manual, Fifth Edition.

This article briefly discusses the low-slope text of the manual's reroofing section. We encourage you to refer to the manual for more information. The manual can be purchased online at shop.nrca.net or by calling NRCA's InfoExpress at (866) ASK-NRCA (275-6722).

Thomas Bollnow is an NRCA senior technical director of technical services, and Joan P. Crowe is an NRCA manager of technical services.

Terms to know

Re-cover: The addition of a new low-slope roof membrane or system over the surface of a major portion of any existing roof assembly. This process leaves in place most or all existing roof materials.

Replacement: The removal of an existing roof system and installation of a new roof system. It also is known as "tear-off and replacement."

Reroofing: The process of re-covering or tearing off and replacing an existing roof system.