Base flashing height limitations originated with bituminous flashing systems and became more sophisticated with heavier mat weights, coatings and inclusion of granulated surfacing. Built-up roofing (BUR) material manufacturers quickly realized granulated bituminous flashings installed with hot asphalt or cement and attached at the top with roofing nails could slip and fall because of the sheet's inability to support its weight.

Some BUR material manufacturers settled on published maximum base flashing heights of 24 inches (610 mm). Anything installed above this height prompted membrane manufacturers to recommend special precautions. This change in height limitation and special precautions caused NRCA to remove the base flashing height limitations in The NRCA Roofing and Waterproofing Manual, Fifth Edition, in 2001, as shown in the detail.

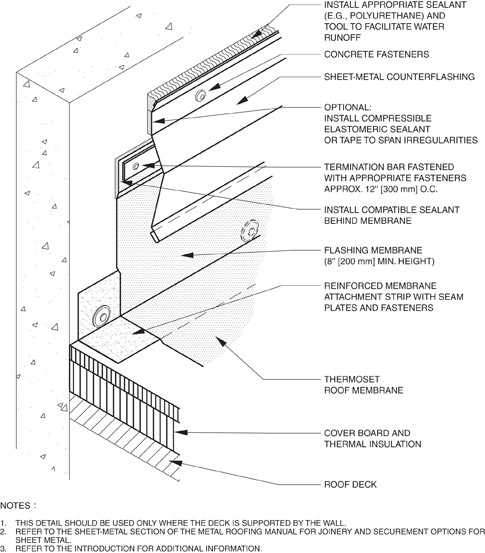

Detail TS-4 from The NRCA Roofing and Waterproofing Manual, Fifth Edition

Flashing height limitations for bituminous roof systems have remained at about 24 inches (610 mm) without special precautions, but the popularity, compatibility and lighter installed weight of thermoset single-ply sheets made single-ply manufacturers rethink this restraint. The average weight per square foot of 60-mil- (0.06-inch- [1.5-mm-]) thick, unreinforced EPDM is about 0.4 pounds per square foot (psf) (2 kg/m2) compared with about 1 psf (5 kg/m2) for one ply of granulated, polyester-reinforced SBS-modified bitumen sheet and a Type IV backer felt.

Thermoset single-ply membrane roof system manufacturers have allowed high-wall fully adhered flashings in excess of 6 feet (2 m) on some projects. When this occurs, several EPDM manufacturers recommend terminating the membrane sheet at about 8 inches (203 mm) up the wall without installing the metal counterflashing. These manufacturers then recommend installing a separate piece of EPDM wall flashing properly lapped over the membrane sheet and installed on the wall. This detail helps eliminate stresses that may occur if one-piece roof-to-high-wall flashings are installed. The wall flashing sheet is terminated with metal counterflashing as shown in the detail. Several thermoset manufacturers prefer high-wall flashings instead of wall covering or cladding materials because the manufacturers claim, if properly installed, the high-wall flashings further prevent any water infiltration.

Chuck Scislo is an NRCA senior director of technical services.