Where a steep-slope asphalt shingle roof system meets a side wall or penetration, such as a chimney or dormer, individual pieces of metal flashing are installed at the end of each shingle course. This is referred to as step flashing and used to ensure water is diverted to the outside of the wall covering.

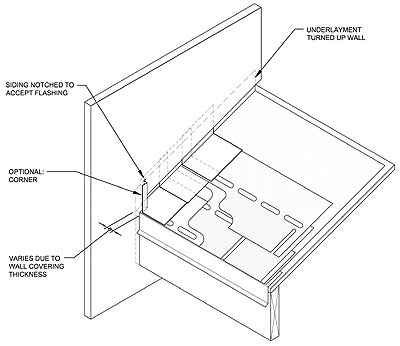

The point where step flashings start and intersect a wall covering can be difficult to weatherproof. In these instances, NRCA suggests the use of a soldered one-piece step flashing at the eave-to-wall interface (see figure).

Figure 20 from the Asphalt Shingle Roof Systems section of The NRCA Roofing and Waterproofing Manual, Fifth Edition

The suggested one-piece step flashing is fabricated with a kickout at the downslope edge. Most of the water that gets behind the wall covering will be diverted onto the shingles' surfaces upward from the eave location.

However, some water will run along the roof-wall interface toward the eave. The kickout portion of the step flashing will direct this water onto the roof surface, preventing it from going behind the wall covering. The dimension of the kickout should equal or be slightly larger than the thickness of the wall covering.

A vertical notch in the siding is required for the installation of this unique piece of step flashing. Also, it may be prudent to install sealant along the top and vertical edges of the exposed portion of the kickout to help prevent water intrusion.

The soldered one-piece step flashing should be installed over the starter course and under the first exposed course of shingles.

The type and thickness of the metal used for step flashing should be commensurate with the anticipated service life of the asphalt shingle roof system. NRCA suggests using metal step flashing that is 7 inches (178 mm) long by 8 inches (203 mm) wide for standard-sized asphalt shingles.

Soldering the joints of the one-piece step flashing is recommended for longevity and durability of its weatherproofing ability instead of joining the seams by overlapping, sealing and installing fasteners. This is because it is difficult to access the flashing piece if there is a maintenance issue.

Other compatible materials with appropriate expected service lives, such as polypropylene co-polymers, may be used.

The detail also applies to slate, tile and wood roof systems. Step flashing is recommended for use with asphalt shingles, slate and wood roof systems instead of a continuous L-shaped flashing piece so water is directed onto the top surface of the roof covering and not the underlayment. However, because of the unique shape of many tiles, continuous channel flashing is used for tiles.

The figure provided here is enhanced with more detailed information than the figures in the steep-slope section of The NRCA Roofing and Waterproofing Manual, Fifth Edition. This figure is the second iteration.

For additional information, refer to The NRCA Steep-slope Roofing Manual.