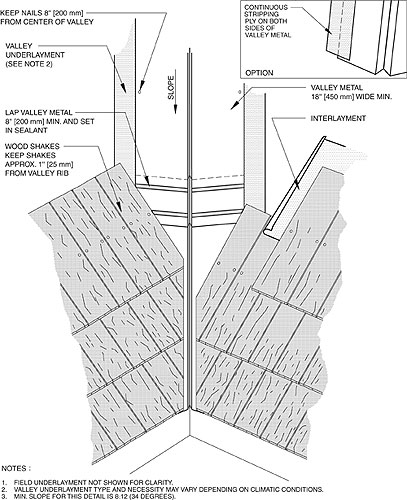

Valley flashing is required for steep-slope wood shake roof systems where two adjoining roof slopes intersect. Detail SHK-7 "Closed Valley" in The NRCA Roofing and Waterproofing Manual, Fifth Edition, provides information for constructing a closed valley with a metal liner for a wood shake roof system.

First, a valley underlayment is installed as secondary protection against water intrusion. NRCA recommends using an 18-inch-wide valley metal to line the valley and provide the primary watershedding protection. Shingle-fashion overlap of the individual valley metal pieces is 8 inches minimum. Two beads of sealant or two-sided butyl tape are required to help prevent water infiltration at the overlap joint.

One key element to implementing this detail successfully is the location of the nails within the valley metal. Nails will penetrate the valley metal; it is impossible to install a wood shake roof system without the nails penetrating the 18-inch-wide valley metal. The farther away the nails are from the center of the valley and the steeper the valley slope, the less likely moisture will be able to infiltrate the nail holes.

Detail SHK-7 from The NRCA Roofing and Waterproofing Manual, Fifth Edition

The cut ends of the shakes are installed with a nominal 1-inch gap between the cut end and center of the valley metal. This allows water to travel freely along the metal's surface without being interrupted by the shakes.

Minimum roof slope for this detail is 8-in-12 (34 degrees). A valley's slope always will be less than the slope of the roof's field. When two equally sloped roof sections meet, the valley slope will be about 70 percent of the slope of the roof's field. If both roof slopes are 8-in-12 (34 degrees), the resulting valley slope will be about 5 1/2-in-12 (25 degrees). A 5 1/2-in-12 (25-degree) slope is less resistant to the possibility of water backup than an 8-in-12 (34-degree) slope.

Wood shake roof systems with lesser slope generally will require an enhanced open valley detail. This will include an additional liner under the valley metal and/or stripping in the edges of the valley metal (as shown in the option box). Wider valley metal and greater overlap of the metal valley pieces also are possible upgrades to this detail.

James R. Kirby is an NRCA senior director of technical services.