In January, NRCA released The NRCA Roofing Manual: Metal Panel and SPF Roof Systems—2008, the second volume in a four-volume series intended to update and supersede The NRCA Roofing and Waterproofing Manual, Fifth Edition. The new manual provides in-depth industry best practices and technical information about the design, materials and installation of quality metal panel and SPF roof systems. A copy of the manual was provided to all NRCA contractor members.

The manual's metal panel roof systems section, which is organized for use as a reference document, provides time-tested, best-practice guidelines applicable throughout the U.S. from knowledgeable, practicing roofing contractors. The manual provides information useful to roofing professionals, as well as building owners.

Following is an overview of the manual's metal panel roof systems section.

General information

Chapter 1—Guidelines Applicable to Metal contains information about common metal types used for the fabrication of roof panels and related accessories. This chapter discusses aluminum, aluminized steel, copper, Galvalume,® galvanized steel, lead, lead-coated copper, stainless steel, terne-coated stainless steel, terne metal and zinc.

The manual divides the metal types into two categories: naturally weathering metals and metallic-coated steel.

Naturally weathering metals do not require coatings for protection; they form their own protective layer by oxidizing sufficiently to withstand environmental exposures common to all roof systems.

Metallic-coated steel refers to carbon-based steel products that are coated with aluminum (aluminized steel), aluminum-zinc alloy (Galvalume), zinc (galvanized steel), or zinc and tin (terne). The metallic coatings serve as a sacrificial layer that protects the base metal by oxidizing and forming a barrier.

Chapter 1 provides an easy-to-read table with metal gauge, thickness and weight information for the metal types used for roof systems. The chapter notes that metals have allowable tolerances for gauge, thickness and weight, and roof system designers should be aware of these tolerances.

The chapter also provides information about weather considerations not included in The NRCA Roofing and Waterproofing Manual, Fifth Edition. For instance, salt spray and coastal proximity exclusions for prepainted steel products are discussed. Minimum distance requirements—from as low as 1,000 feet up to 1 mile—may be included.

Additionally, Chapter 1 discusses protective coatings, such as fluoropolymers, and siliconized acrylic and polyester paint systems, laminates and anodizing, which are methods used to protect and enhance metal roof panels. Roofing professionals will find this information useful when selecting coatings. Although clear-coat finishes provide many benefits, such as additional resistance to scratching and scuffing, they may exacerbate the visual effects of oil canning.

Two additional topics, galvanic series and oil canning, are important yet often misunderstood topics in the metal roofing industry. The chapter provides clear, concise information about both topics. Contractors will find the commentary about how oil canning does not affect a metal panel roof system's structural or weatherproofing capabilities especially useful.

Metal panels

Chapter 2—Guidelines Applicable to Metal Panel Roof Systems contains information about metal panel roof system types and panel and seam configurations, as well as specifics about panels and system installation.

The chapter offers definitions of "architectural metal panel roof system" and "structural metal panel roof assembly." Subcategories of metal panel roof systems also are highlighted, including hybrid systems, exposed fastener systems and metal shingle panels.

New information about curved panels is included in the chapter's panel configurations portion. Because curved metal panels are being specified and installed more often, the information is extremely relevant for current metal roof system designs.

Advancements in metal-forming equipment allow installers and manufacturers to fabricate curved panels with 1- to 2-inch seam heights. Aluminum and copper panels can be arched with radii as low as 24 inches, and steel panels can be arched with radii as low as 60 inches. Curved panels often are installed below the recommended 1/2-in-12 (2.4-degree) slope for structural metal panel roof systems and 3-in-12 (14-degree) slope for architectural metal panel roof systems, so designers should consider seam type for weatherproofing and ability to fabricate the seams in the field. Upgrading or enhancing underlayment for curved systems also may be prudent.

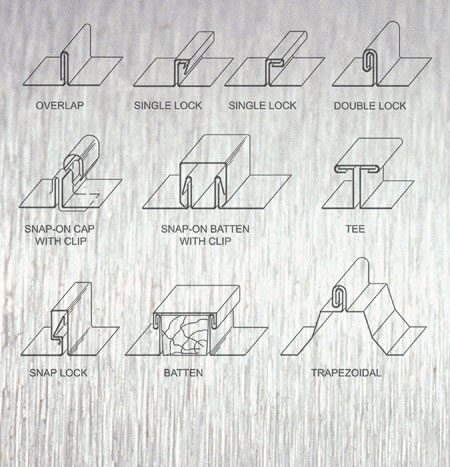

Seam types—flat and standing—are discussed, as well. According to the manual, the term "standing-seam panel" specifically refers to metal panels that interlock or are seamed together vertically above a panel's pan. Seaming methods—mechanical, snap-together, integral and hooked—are explained, and figures are provided (see Figure 1).

Figure 1: Seaming methods

A premanufactured panel's length generally is limited by shipping constraints. Similarly, an on-site-fabricated panel's length is limited by lifting and safe-handling requirements. Additional information about panel length and width is provided in Chapter 2.

The manual briefly discusses vapor retarder use in hot-humid, hot-dry and cold climates. This is intended to begin the thought process regarding the use of vapor retarders in metal panel roof systems.

Considerable information about metal panel layout and fastening/attachment also is provided in Chapter 2, including discussion about deck considerations, panel aesthetics based on layout, and fastener and clip selection. Fastener and clip selection and installation are critical for a metal panel roof system's uplift resistance. If panels are being roll-formed with portable equipment, fastening requirements may be available from equipment manufacturers as part of wind-uplift tests.

Fixed points, in combination with metal panels' expansion and contraction, also are important design and installation considerations. Chapter 2 provides methods to determine panel movement based on material type, panel length and temperature change. Knowing the anticipated panel movement allows construction details to be designed to accommodate it.

Because metal panels can be installed over existing metal panel roof systems, information to assist roofing professionals performing reroofing also is provided.

Structural substrates

The most common types of continuous or closely spaced substrates for architectural metal panel roof systems—steel, wood panels, wood planks and wood boards—are discussed in Chapter 3—Structural Substrates for Metal Panel Roof Systems.

Chapter 3 begins with a commentary about guidelines applicable to all substrates for metal panel roof systems: Dimensional stability, fire resistance, deflection, expansion joints, slope and drainage are addressed.

Also in this chapter is a discussion about the most common types of spaced structural supports for structural metal panel roof assemblies—steel joists, light-gauge framing and purlins. Purlins can be used with light-gauge framing or installed over a solid substrate, such as cementitious wood-fiber deck panels or concrete roof decks.

It is important to note the NRCA manual series' four volumes are intended to be used with each other. Because many roof deck types are thoroughly discussed in The NRCA Roofing Manual: Low-slope Membrane Roof Systems—2007, some of the discussion in the metal panel roof systems manual about decks is brief, and readers are directed to find additional information in the 2007 manual.

Insulation and vapor retarders are important considerations for metal panel roof systems. Chapter 3 briefly discusses these with a reference to the Moisture Control section of The NRCA Roofing and Waterproofing Manual, Fifth Edition. Understanding how insulation and vapor retarders can help prevent unwanted moisture from entering a roof system is valuable information for designers and specifiers of all roof systems.

Architectural and structural

Chapter 4—Architectural Metal Panel Roof Systems and Chapter 5—Structural Metal Panel Roof Assemblies are similar; however, the chapters are specifically focused. Each chapter begins by defining its respective roof system type.

Architectural metal panel roof systems typically are considered water-shedding, require a continuous or closely spaced deck, and are used for steep-slope applications. Structural metal panel roof assemblies typically are considered weatherproof, capable of spanning structural members and used for low-slope applications. Based on these definitions, NRCA provides specific design and installation information for both metal panel roof system types.

Because underlayments commonly are used over solid substrates, only Chapter 4 includes a thorough discussion of underlayment types, including ice-dam protection membranes.

Both chapters discuss insulation. Rigid insulation and attachment methods, such as Z-purlins, batten/counterbatten systems and bearing plates are mentioned. Installation considerations for blanket insulation and associated vapor retarders are discussed only in Chapter 5.

Ventilation, vapor drive and considerations for vapor retarders also appear in both chapters; the chapters are tailored to apply to their respective roof systems.

Additionally, panel profiles are addressed. For architectural systems, panel profiles typically are based on seam type. For example, double- and single-lock seams, snap-lock seams and snap-on seams are shown in Chapter 4. For structural assemblies, there are three profile types: trapezoidal, intermediate rib and vertical leg.

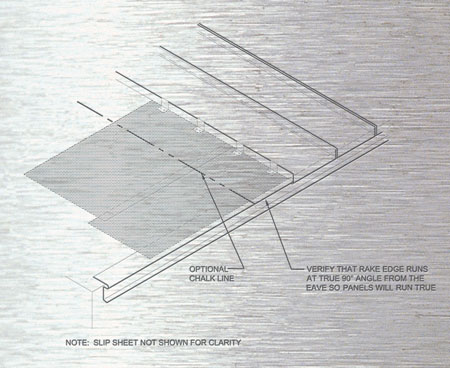

Considerable discussion about panel installation and fastening/attachment is provided, as well. For example, a panel layout plan can help verify the correct panel size and number of panels that will be required for a job. Planning the layout before installation can help a designer or installer aesthetically blend a roof system with building lines, shapes and symmetry. Marking a substrate with chalk lines can help ensure panels run at 90-degree angles to a roof's eave (see Figure 2).

Figure 2: Marking a substrate with chalk lines can help ensure panels run at 90-degree angles to a roof's eave.

Edge-metal flashing is recommended for architectural metal panel roof systems to ensure proper attachment and uplift resistance at eaves. Edge-metal flashing or mechanical attachment is recommended for structural metal panel roof assemblies.

Designers should not overlook the importance of overall positive drainage. Additionally, localized positive drainage must be provided to ensure water does not come to rest behind projections through a roof, such as skylights and chimneys.

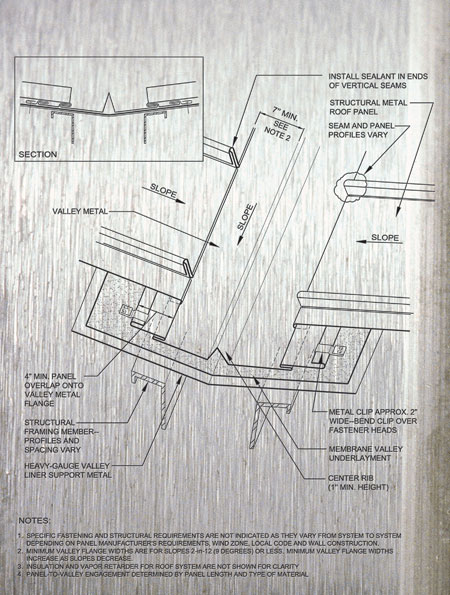

Chapters 4 and 5 provide significant insight regarding sheet-metal flashings at eaves, rakes, gutters, valleys and penetrations. Eaves and rakes serve as attachment points and are critical for uplift resistance. Gutters and valleys control the removal of water from a roof. Details are critical to a roof system's overall success; therefore, these chapters present considerable information regarding these important topics .

Additionally, there is information about roof system accessories, such as snow guards, skylights, walkways, counterflashing and wall panels.

Details

Chapter 6—Construction Details provides an introduction to details for use with the construction details as a supplement to the special notes on the individual construction details.

For example, a letter designation for certain details is included. This identifies NRCA's order of preference for addressing a specific detail condition.

Figure 3: NRCA's metal manual provides parallel sets of details for three metal panel types.

The introduction includes topics such as preservative-treated wood, job site-fabricated components, wood nailers and blocking, counterflashing alternatives, parapet walls and rooftop equipment flashing.

The major change from the The NRCA Roofing and Waterproofing Manual, Fifth Edition is the differentiation of NRCA's metal panel details. The new manual includes construction details for architectural metal panels, structural trapezoidal seam metal panels and structural vertical seam metal panels. Providing multiple, parallel sets of details gives roofing contractors the opportunity to use NRCA's construction details in submittal packages (see Figure 3). This is noteworthy for contractors and designers who use the NRCA manual series.

Familiarize yourself

I encourage professional roofing contractors, designers and specifiers to become familiar with the information in The NRCA Roofing Manual: Metal Panel and SPF Roof Systems—2008, as well as The NRCA Roofing Manual: Low-slope Roof Systems—2007. The NRCA Roofing Manual: Steep-slope Roof Systems—2009 will be available in January 2009. NRCA manuals are available at shop.nrca.net.

James R. Kirby, AIA, is NRCA's associate executive director of technical communications.