During summer, it is not unusual for someone to ask: "Is it cool enough for you?" Typically, this question refers to whether the air conditioning in a house or car is set to a low enough temperature. However, now this question also could refer to a roof system's relative "coolness."

With rising oil prices, virtually everyone can feel the effects of spiking energy costs at home and in business, and there is ongoing pressure to become more energy-efficient. And no one can escape the constant media barrage regarding global warming and climate change.

Although roofing contractors are obliged to comply with local building codes and many are beginning to build "green," new initiatives for cool roofing—ranging from voluntary green building programs to heightened code requirements—are inducing change quickly. And the rush to conserve energy easily can cause confusion about compliance with these new initiatives. In some instances, local mandatory code requirements and voluntary green building programs even have competing or overlapping cool roofing initiatives.

Against this backdrop, this article will explain how metal roofing—unpainted, oven-baked paint finishes or granular-coated surfaces—can be a viable option to help conserve energy by reducing cooling loads and lowering the urban heat island effect. (Lowering the urban heat island effect has a secondary effect on lowering cooling loads around a building because ambient temperatures are lowered.)

New technology

The metal roofing industry has responded to cool roofing initiatives by developing several new technologies.

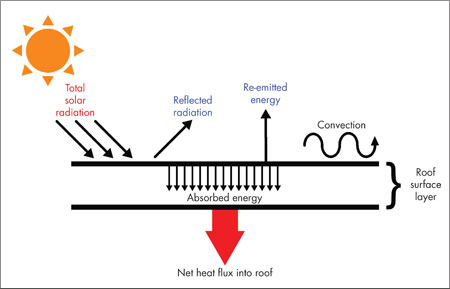

Generally, metal roofing's relative "coolness" is determined by its reflectivity and emissivity. As the figure demonstrates, when solar radiation strikes a roof surface, some of that radiation—up to 70 percent—is reflected to the sky. Therefore, a roof surface with high reflectivity remains cooler and less heat is transferred into the building or convected into ambient air.

This illustration shows how sunlight can be reflected or absorbed by a roof system.

Factory-painted metal roofing is now cooler because it's more reflective than ever with the use of infrared reflective pigment technology. Infrared reflective pigment is available in darker colors but with reflective properties similar to white or lighter colors. It also allows up to 90 percent of the solar radiation absorbed by roof surfaces to be re-emitted as infrared light. (This works especially well with granular-coated surfaces.)

Infrared reflective pigment's beneficial effect is well-demonstrated by two schools in Paulding County, Ga., which were built six months apart between 2002-03.

Baggett Elementary was given a Hunter Green Kynar 500®-based painted metal roof system with conventional pigment. Then, Poole Elementary was given the same color roof system but with infrared reflective pigment. With their thermostats controlled by the county and virtually all factors made equal in the two buildings, such as size and solar orientation, Poole Elementary is saving $15,000 more than Baggett Elementary annually in energy costs (based on electricity and gas bills from GreyStone Power Corp., Douglasville, Ga.). Infrared reflective pigment costs about the same as conventional pigment, resulting in quick payback.

Oak Ridge National Laboratory, Oak Ridge, Tenn., is testing another aspect of metal roofing that is showing promise for steep-slope applications—above-sheathing ventilation.

Using vertical battens or stand-off clips to raise a metal roof system, an air gap is created above the deck, nominally 3/4 of an inch. This allows air to circulate upward from the eaves to the ridge for venting, creating two benefits: During summer, some energy absorbed by the roof surface is convected away before it can enter the building envelope, and during winter, the gap of still air acts as an insulation layer. Further testing is planned to reinforce these findings.

New(er) rating systems

North America has several green building rating systems for commercial and residential buildings. These systems measure how construction professionals plan, design and use materials in ways that reduce the environmental effects caused by constructing and operating buildings. Green building projects typically are registered, evaluated, documented and recognized for the achievement levels they attain.

Metal roofing can contribute one or more points to a green building's rating in several ways.

For example, some green building rating systems use steep-slope or low-slope solar reflectance index (SRI) values to define cool roofs that reduce the heat island effect. SRI is a calculated value that includes reflectance and emissivity. A cool metal roof can be selected that meets or exceeds the minimum required SRI value, thus earning one of the points needed in the final tally for a project rating.

Also, green building rating systems reward recycled content and end-of-life recyclability. Steel contains an average 25 percent minimum recycled content. At the end of its life, steel is 100 percent recyclable, helping to significantly reduce construction waste. Finally, a building's overall energy design may benefit from cool metal roofing, helping to reduce heat transfer into the building envelope.

The U.S. Green Building Council's (USGBC's) Leadership in Energy and Environmental Design® (LEED) Green Building Rating System™ is the dominant green building rating system. LEED's competitor in North America is Green Globes,™ a voluntary green building rating system developed by The Green Building Initiative, Portland, Ore., that is completing American National Standards Institute certification through the consensus process.

LEED and Green Globes use SRI values to define a low-slope cool roof system as having a minimum SRI value of 78 and steep-slope cool roof system as having a minimum SRI value of 29. Many metal roofing products qualify for these values, especially those with infrared reflective pigments.

A new aspect of LEED and Green Globes that is gaining ground is the use of life-cycle inventory (LCI) and life-cycle assessment (LCA). Green Globes currently includes a version of Merrickville, Ontario-based The Athena® Institute's EcoCalculator for Assemblies, a tool for evaluating LCI and LCA parameters such as global warming potential, fossil fuel depletion, embodied energy, emissions, etc. The tool provides various ratings for construction materials and their effects on a building's operational life.

When LEED 2009 is launched, it also likely will incorporate the Athena EcoCalculator for Assemblies as it replaces certain existing credits, such as recycled content and construction waste management (recyclability).

Proposed ASHRAE standard

ASHRAE 90.1, "Energy Efficient Design of New Buildings Except Low-Rise Residential Buildings," has been adopted by many jurisdictions. Among requirements for building envelope energy performance, the standard—which also uses SRI values to define cool roof systems—provides an insulation credit for roof systems with minimum reflectances of 0.70 and minimum emissivities of 0.75, comparable to California's 2005 Title 24 Energy Code. This is beneficial in most areas of North America where the annual cooling energy savings exceed added annual heating costs incurred during winter from cool roofs.

The American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) also is in the process of advancing a new standard.

ASHRAE Standard 189.1P, "Standard for the Design of High-Performance Green Buildings Except Low-Rise Residential Buildings," is co-sponsored by USGBC and the Illuminating Engineering Society of North America. It essentially is a hybrid of minimum prescriptive performance requirements and voluntary green building certification.

By design, the standard mimics the LEED Green Building Rating System. For cool roofing, it calls for a minimum SRI value of 78 for low-slope roof systems and a minimum SRI value of 29 for steep-slope roof systems. However, in contrast to LEED, the proposed standard is written in code language. Therefore, what was a voluntary green building rating system is now being written for jurisdictions to be adopted throughout the U.S. as mandatory code.

The proposed standard has many implications if adopted in its present form, including enforcement complexities, and is being watched closely by potentially affected industries. Meanwhile, cool metal roofing would benefit from its adoption because more building owners would seek its benefits.

New energy code

Having completed its three-year revision cycle, California's 2008 Title 24 Energy Code is expected to become effective in July 2009. For now, the 2005 code continues its minimum requirements for solar reflectance of 0.70 and thermal emissivity of 0.75. If these prescriptive minimums are not met, a designer may choose an alternative method to comply, namely a whole building design approach or energy trade-off analysis.

To make these alternative methods easier to implement, the Cool Metal Roofing Coalition engaged EnergySoft LLC, Novato, Calif., to create a free downloadable program for owners of EnergySoft's EnergyPro, the energy design tool of choice for commercial building energy analysis and documentation in the state of California.

The program leads a designer through steps for prescriptive compliance and, if needed, a whole building design or trade-off analysis.

California's 2008 Title 24 Energy Code will be more stringent for low-slope nonresidential, high-rise residential and hotel/motel buildings. It also will introduce provisions for reflective roofing in residential construction and will require aged values for solar reflectance as they become available through the Cool Roof Rating Council (CRRC). For products that have not yet been registered in the CRRC product directory, the code specifies default reflectance and emittance values. Also, SRI will be an alternative to meeting separate solar reflectance and thermal emittance requirements.

The Cool Metal Roofing Coalition is working with the California Energy Commission to develop the Nonresidential Alternative Calculation Method Approval Manual and Nonresidential Compliance Manual.

A strong role

With so much happening with cool roofing, it is not surprising new mandatory code and voluntary green building initiatives are competing and overlapping. For instance, an architect designing a California public building must obtain LEED Silver level certification and comply with California's Title 24 Energy Code.

Cool metal roofing clearly contributes to contractors' need for mandatory code requirements and voluntary green initiatives even as they seem to converge. These matters will sort themselves out in the marketplace and policy arenas; meanwhile, cool metal roofing will continue to play a strong role in achieving "cool" compliance while providing low maintenance and long, credible service life.

Gregory L. Crawford is the Cool Metal Roofing Coalition's executive director.