Asphalt shingle manufacturers and the Asphalt Roofing Manufacturers Association (ARMA) are beginning to introduce a new methodology for testing and reporting the wind resistances of asphalt shingles. Following is a brief overview of this new methodology and how designers and contractors can use it.

Background

Unlike membrane-type roof systems (built-up, single-plies), which provide for continuous air barriers, asphalt shingle roof systems are recognized to be air-permeable. As a result, conventional wind-test methods do not yield representative results when used on asphalt shingle roof systems.

Since the early 1990s, asphalt shingle manufacturers and ARMA have conducted extensive research into better quantifying the wind resistances of asphalt shingle products. The research culminated in the development of two new test methods: UL 2390, "Test method for wind resistance of asphalt shingles with sealed tabs," and ASTM D6381, "Standard Test Method for Measurement for Asphalt Shingle Tab Mechanical Uplift Resistance."

New methodology

UL 2390 and ASTM D6381 serve as the technical basis for the new wind-resistance methodology for asphalt shingles.

UL 2390 measures an asphalt shingle's flexural modulus (stiffness), regions (areas) in front of and behind the shingle's self-seal strips, and pressure coefficients, taking into consideration the air-permeable nature of asphalt shingle roof systems. A shingle's uplift coefficients in front of and behind the self-seal strip are multiplied by the area, and a resultant uplift force (load) on the shingle is determined.

ASTM D6381 then is used to determine a shingle's resistance to uplift forces. The uplift-resistance value is compared with the shingle's uplift-load value (derived from UL 2390); safety factors are added; and the appropriateness of a specific shingle for specific wind speed is determined.

UL classification

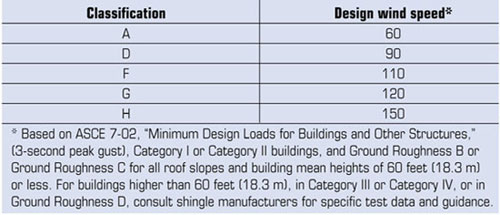

Because this new methodology involves relatively complex engineering and aerodynamics calculations, direct implementation of UL 2390 and ASTM D6381 into the U.S. roofing industry is not practical. To account for this, asphalt shingle manufacturers are working with Underwriters Laboratories (UL) Inc. to develop a classification system that will provide for uniform reporting of asphalt shingles' wind resistances using the new methodology. Using this classification system, asphalt shingle products will receive a wind-resistance classification. These classifications and corresponding design wind speeds are provided in the figure.

Shingles' wind-resistance classifications by design wind speeds

The classifications will be included on shingle package wrappers, manufacturers' product literature and in the "Prepared roof covering materials, Asphalt shingle wind resistance (TGAH)" section of future editions of UL's Roofing Materials and Systems Directory.

One specific issue to be cautious of is the classification letter designations for the wind-resistance classifications are in reverse order of UL's fire-resistance classifications. For example, a UL Class A fire-resistance rating designates UL's highest level of fire resistance, but UL's Class A wind-resistance rating designates UL's lowest tested level of wind resistance. Care must be taken not to confuse the two classifications.

Closing thoughts

The development and implementation of this new methodology is a major step toward more accurately measuring and improving the wind performances of asphalt shingles.

If you install asphalt shingles, I encourage you to become familiar with the new UL classification system. In the coming months, asphalt shingle manufacturers and UL will have additional information available, which should be of further assistance.

Mark S. Graham is NRCA's associate executive director of technical services.