NRCA has conducted limited testing of polymer-modified bitumen sheet products. This testing is a follow-up to similar testing conducted in 2011 where 10 of the 16 products evaluated did not achieve physical property levels prescribed in ASTM International product standards.

Product testing

In 2015, NRCA obtained full rolls of 13 new (uninstalled) polymer-modified bitumen sheet products from eight manufacturers; 11 products were SBS polymer-modified, and two were APP polymer-modified. The samples were obtained from NRCA contractor members throughout the U.S. from their stored stocks.

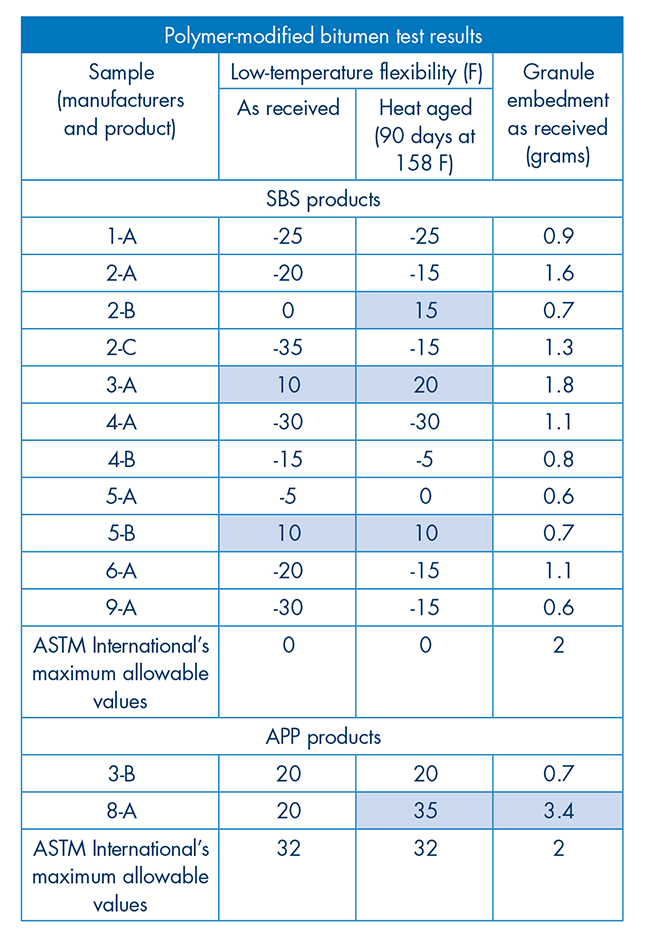

Product specimens were tested for low-temperature flexibility before and after heat aging and granule loss according to applicable ASTM International test methods. Test results are shown in the figure.

The ASTM International product standards for polymer-modified bitumen sheet products provide for a maximum allowable low-temperature flexibility value of 0 F for SBS products and 32 F for APP products. Three of the 11 SBS products and one of the two APP products tested do not comply with ASTM International's low-temperature flexibility requirements.

ASTM International product standards provide for a maximum allowable granule loss value of 2 grams for SBS and APP products. One APP product did not comply with ASTM International's granule loss requirement.

Analyzing the results

NRCA's Technical Operations Committee has overseen and reviewed the test results. NRCA recognizes the sampling used in this limited test program may not be statistically representative of all polymer-modified bitumen sheet products being manufactured.

NRCA's testing reveals physical properties of polymer-modified bitumen sheets vary widely.

Results of NRCA's 2015 testing of polymer-modified bitumen sheets. Shaded values denote those exceeding ASTM International's maximum allowable requirements. |

Also, four of the 13 sheet products tested in 2015 and 10 of the 16 tested in 2011 did not achieve the levels prescribed in ASTM International's applicable product standards, which is cause for some concern.

There are a number of reasons why specific products may not achieve adequate low-temperature flexibility values, including inadequate polymer content and inadequate polymer dispersion during manufacturing. Variability in and a lack of adequate quality control during manufacturing likely are exacerbating factors.

To address these concerns, NRCA encourages specifiers and purchasers of polymer-modified bitumen sheets to seek products with a third-party certification of compliance with the applicable ASTM International product standard. An Underwriters Laboratories Inc. product certification is one example of a third-party certification of compliance. Also, products recognized by ICC-ES or Miami-Dade County typically incorporate third-party certifications of compliance.

Additional information regarding polymer-modified sheet products is provided in Chapter 5-Roof Membranes of The NRCA Roofing Manual: Membrane Roof Systems—2015.

Mark S. Graham is NRCA's vice president of technical services.