NRCA and the Midwest Roofing Contractors Association (MRCA) have conducted limited testing of polymer-modified bitumen sheet products. The tests' results show some products do not comply with applicable physical property requirements, which is cause for concern.

Product testing

To conduct the tests, NRCA and MRCA obtained full rolls of uninstalled polymer-modified bitumen sheet products from roofing contractors' and distributors' warehouse stock. Sixteen products from seven manufacturers were tested; 13 of the products were SBS polymer-modified bitumen membranes, and three were APP polymer-modified bitumen membranes.

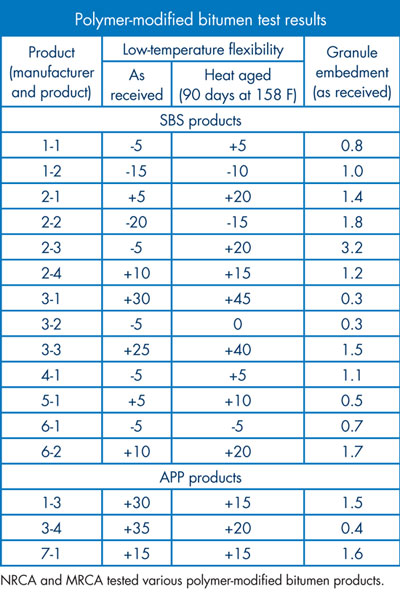

Product specimens were subjected to low-temperature flexibility and granule embedment testing by a recognized testing laboratory. Low-temperature flexibility testing was conducted before and after heating aging according to applicable ASTM International product standards' prescribed methods. Granule embedment testing was conducted in products' as-received conditions according to the product standard's prescribed methods. Test results are shown in the figure.

The ASTM International product standards for polymer-modified bitumen provide for a maximum allowable low-temperature flexibility value of 0 F for SBS products and 32 F for APP products. Only four of the SBS products and two of the APP products tested comply with ASTM International's requirements for low-temperature flexibility.

NRCA and MRCA tested various polymer-modified bitumen products.

For granule embedment, ASTM International product standards provide for a maximum allowable low-temperature flexibility value of 2 grams. Fifteen of the 16 products tested comply with the standards' requirements for granule embedment.

A cause for concern

Although the NRCA and MRCA testing is limited and clearly not statistically representative of all polymer-modified bitumen sheet products, the finding that 10 of the 16 products tested did not achieve the levels prescribed in ASTM International product standards for low-temperature flexibility is cause for some concern.

There are a number of reasons why specific products may not achieve adequate cold-temperature flexibility values, including inadequate polymer content and inadequate polymer dispersion during manufacturing. Also, during the manufacture of polyester-reinforced SBS polymer-modified bitumen sheet products, polyester reinforcements sometimes are precoated with nonmodified asphalt before SBS polymer-modified bitumen is applied to topside and bottomside coatings. Although the standards permit this practice, NRCA and MRCA discourage it because it can affect products' physical properties and long-term performances.

On the other hand, the results for granule embedment testing are somewhat encouraging. Several years ago, MRCA conducted granule-embedment testing of various polymer-modified bitumen products and found many products tested did not comply with the maximum granule loss values prescribed by ASTM International. The finding in the current testing that all but one of the products tested comply with the standards' prescribed level for granule embedment is a positive development.

Mark S. Graham is NRCA's associate executive director of technical services.