FM Global's 2006 revisions to its wind-related guidelines have renewed interest and caused considerable discussion within the U.S. roofing industry regarding proper wind-resistant design for low-slope roof systems. For more than 20 years, many in the industry have referred to FM Global's product testing and certifications subsidiary, FM Approvals, for guidance when designing, specifying and installing low-slope roof systems. However, because of FM Global's revisions to its guidelines, some in the industry are rethinking their reliance on FM Global and FM Approvals and taking a different, more fundamental approach to designing roof systems' wind resistances.

The fundamentals

The fundamental concept of wind design as it applies to roof systems is that the design wind-resistance (uplift-resistance) capacity of a building's roof system should be greater than or equal to the design wind loads that will act upon the roof system. This relationship is expressed mathematically as: wr = wl where wr = design wind resistance and wl = design wind load.

In the event actual wind loads exceed a roof system's wind-resistance capacity, the roof system may not be considered wind-resistant and blow-off is possible.

To properly determine appropriate wind-resistant designs for roof systems, roof system designers accurately must determine design wind loads and wind-resistance capacities. Because these values depend on building location, height and configuration, this determination is best conducted on a project-specific basis.

I discourage roof system designers from arbitrarily assuming roof systems' design wind loads or specifying roof systems with what are thought to be excessively high wind-resistance capacity ratings in the hope these ratings adequately will cover the wind loads. The first practice may result in inadequately accounting for necessary design wind loads. And specifying unnecessarily high wind-resistance ratings likely will result in excessive roof system costs with little or no additional benefit to building owners.

Design wind loads

The recognized standard for determining design wind loads on buildings is ASCE 7, "Minimum Design Loads for Buildings and Other Structures." This consensus standard widely is accepted by engineering and design professionals. The 2005 edition of ASCE 7, designated as ASCE 7-05, is referenced in and serves as the technical basis for wind-load determination in the International Building Code, 2006 Edition, (IBC) and NFPA 5000®: Building Construction and Safety Code (NFPA 5000). Previous editions of ASCE 7 are referenced in the codes' previous editions and legacy model buildings codes (The BOCA National Building Code, Standard Building Code and Uniform Building Code).

ASCE 7-05's guidelines applicable to determining wind loads are provided in Chapter 6—Wind Loads, which provides three wind-load determination methods: Method 1—Simplified Procedure, Method 2—Analytical Procedure and Method 3—Wind Tunnel Procedure.

Method 1—Simplified Procedure uses a series of look-up tables to determine design wind loads and is limited to many common building types. The method's limitations include simple diaphragm, regular-shaped, enclosed buildings with mean roof heights of 60 feet or less, making it applicable to most common building types. Use of this simplified method generally is intended for users who do not necessarily have extensive engineering-based knowledge of wind-load determination.

NRCA's online wind-load calculator, www.roofwinddesigner.com, is based on ASCE 7-05's Method 1. (For additional information, see "NRCA's wind-load calculator," February issue, page 26.)

Method 2—Analytical Procedure is a calculation-based wind-load determination method generally used by design professionals who are experienced in wind-load determination. Although this method also contains some limitations (it only is for regularly shaped buildings), it does not contain some of the other limitations, such as mean roof height of 60 feet or less, of Method 1.

Method 3—Wind Tunnel Procedure provides guidelines for determining wind loads by wind-tunnel testing. This complex, costly procedure is intended for situations where Methods 1 and 2 may not be applicable, such as with unusually shaped or tall buildings.

In each of ASCE 7's three methods, three design wind-load values are determined and referred to as being applicable to Zones 1, 2 and 3 of a building's roof area. Zone 1 applies to a roof's field; Zone 2 applies to a roof's perimeter regions; and Zone 3 typically applies to a roof's corner regions.

Another wind-load determination method used by some roofing professionals is FM Global's Loss Prevention Data Sheet 1-28, "Design Wind Loads" (FM 1-28). This document, which includes a series of relatively complex look-up tables and lengthy commentary, provides FM Global's recommended wind-load determination guidelines intended for FM-insured buildings.

FM Global indicates the technical basis of FM 1-28 is the 1998 edition of ASCE 7, and FM Global makes several relatively conservative assumptions. For example, FM 1-28 assumes an importance factor of 1.15 for all buildings and structures while ASCE 7 uses importance factors ranging from 0.77 to 1.15, depending on a building's occupancy type.

According to ASCE 7, an importance factor of 1.15 only applies to buildings and structures that represent substantial hazard to human life (ASCE 7 Occupancy Category III) and those designated as essential facilities (ASCE 7 Occupancy Category IV). Examples of essential facilities include hospitals, fire stations and police stations. ASCE 7 uses an importance factor of 1.00 for most building occupancies (ASCE 7 Occupancy Category II) and permits use of an importance factor as low as 0.77 for some buildings and structures that represent a low hazard to human life in the event of failure.

As a result of FM Global's conservative importance factor usage, design wind loads for many buildings determined using FM 1-28 may be from 15 percent to 49 percent greater than the results derived from using ASCE 7.

On this basis, I do not recommend roofing professionals rely on FM 1-28 to determine design wind loads except for FM Global-insured buildings where its use may be required by FM Global. Also, because FM 1-28 is not based specifically on the current edition of ASCE 7-05, results derived using FM 1-28 may not be interpreted as being compliant with IBC and NFPA 5000 requirements.

Safety factor

To provide reasonable assurance that a roof system's wind-resistance capacity is greater than design loads, engineering and wind-design practices call for safety factors to be applied to roof systems' design wind loads.

Safety factors for building materials, components and systems typically vary in magnitude based on a number of factors, including the materials being used and complexity of building system components. For low-slope membrane roof systems, a minimum safety factor of 2.0 typically is considered appropriate.

ASTM D6630, "Standard Guide for Low Slope Insulated Roof Membrane Assembly Performance," which is a recognized consensus standard, prescribes, "Roof system wind uplift resistance shall have a minimum 2.0 factor of safety."

For roof systems, this safety factor accounts for usually anticipated variances in materials and construction and possible deterioration of materials' physical properties as a result of aging.

Once a safety factor is accounted for, the recognized engineering concept is that a roof system's recommended minimum design wind-resistance capacity should be at least two times larger than the design wind load for a low-slope membrane roof system to be considered adequately wind-resistant. This is mathematically expressed as: wr min. = 2.0 x wl where wr min. = minimum recommended design wind resistance and wl = design wind load. 2.0 represents the assigned safety factor.

Wind-resistance capacity

Roof systems' abilities to resist wind loads often are referred to as their wind-resistance capacities. For most low-slope membrane roof systems, wind-resistance capacities are determined by laboratory testing.

IBC and NFPA 5000 prescribe four laboratory test methods for determining low-slope membrane roof systems' wind-resistance capacities: FM 4450, FM 4470, UL 580 and UL 1897. Roof systems need only satisfy one of these four test methods to be considered adequately wind-resistant.

FM 4450, "Approval Standard for Class 1 Insulated Steel Roof Decks," and FM 4470, "Approval Standard for Class 1 Roof Covers," provide a series of laboratory test methods to determine roof systems' combustibility (fire resistance), wind resistance, corrosion resistance, impact resistance and susceptibility to heat damage. The wind-uplift resistance portions of these test methods are similar and based on another test method, FM 4474, "Evaluating the Simulated Wind Uplift Resistance of Roof Assemblies Using Static Positive and/or Negative Differential Pressures."

FM 4450 and FM 4470 are FM Approvals' internally developed guidelines and not considered to be recognized consensus standards. FM 4474 has been developed and is maintained using an American National Standards Institute- (ANSI-) accredited process and is considered a recognized consensus standard.

With FM 4474, either a small-scale (2- by 2-foot) bench test, 5- by 9-foot test apparatus or 12- by 24-foot test apparatus is used depending on the roof system type and roof deck substrate being analyzed. Testing is conducted at graduated, increasing pressure increments held at 15-pounds-per-square-foot increments for a minimum of 60 seconds. Then, the pressure is increased to the next increment until failure or the test is suspended. Results typically are reported as the highest pressure level maintained for a 60-second period.

FM 4474's classification designations 60, 75, 90 and so forth indicate roof systems having tested wind-resistance capacities of 60 pounds per square foot, 75 pounds per square foot and 90 pounds per square foot, respectively. These designations are similar to the 1-60, 1-75 and 1-90 classifications derived from FM 4450 and FM 4470; the "1-" portion of the designation applies to the tested system's combustibility classification.

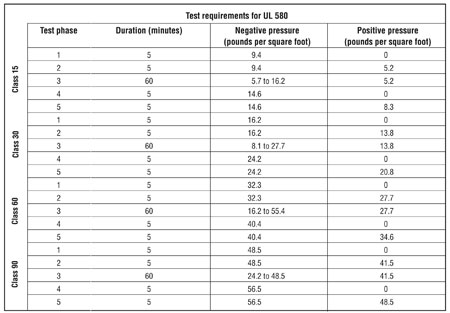

UL 580, "Tests for Uplift Resistance of Roof Assemblies," consists of a 10- by 10-foot test apparatus that creates uniform positive pressures on the bottom side of a roof deck and oscillating negative pressures on the top side of a roof membrane specimen. Test cycling and duration are indicated in the figure.

UL 580's, "Test for Uplift Resistance of Roof Assemblies," negative and positive test-pressure cycling for Classes 15, 30, 60 and 90

UL 580 has been developed and is maintained using Underwriters Laboratories Inc.'s standards technical panel, which is considered a consensus process and recognized by the model codes as meeting the requirements for reference standards.

Based on UL 580, a Class 30 rating is assigned to tested roof systems that successfully complete the 80-minute Class 30 cycle. A Class 60 rating is assigned to tested roof systems that successfully complete the 160-minute Class 30 and Class 60 cycles. A Class 90 rating is assigned to tested roof systems that successfully complete the 240-minute Class 30, Class 60 and Class 90 cycles.

UL 1897, "Uplift Tests for Roof Covering Systems," consists of a 10- by 10-foot apparatus that creates a steady negative static pressure on the top side of a roof membrane specimen. A test pressure differential of 15 pounds per square foot is applied to the specimen and held for one minute. Thereafter, the pressure is raised in 15-pounds-per-square-foot increments and held for one minute each. These incremental increases are continued until failure or the test is suspended. UL 1897 has been developed and is maintained using an ANSI-accredited process and is considered a recognized consensus standard.

Based on UL 1897, a Class 30 rating is assigned to roof system specimens that successfully complete the 15-pounds-per-square-foot and 30-pounds-per-square-foot increments. A Class 60 rating is assigned to roof system specimens that successfully complete Class 30 testing and additional 45-pounds-per-square-foot and 60-pounds-per-square-foot increments of testing. Roof system specimens that successfully complete Class 60 testing and additional 75-pounds-per-square-foot and 90-pounds-per-square-foot increments of testing receive Class 90 ratings.

For loose-laid, ballasted single-ply membrane roof systems, FM 4450, FM 4470, FM 4474, UL 580 and UL 1897 do not apply. Instead, IBC and NFPA 5000 prescribe wind resistances be designed according to ANSI/SPRI RP 4, "Wind Design Standard for Ballasted Single-Ply Roofing Systems."

Roof system selection

Once design wind loads and minimum recommended design wind resistances (including a safety factor) for a building's roof system are determined, roof system designers can select appropriate wind-resistant roof systems that have tested capacities equal to or greater than the minimum recommended design wind resistances.

Roof systems' wind-resistance capacities that have been tested and currently are approved by FM Approvals in accordance with FM 4474, FM 4450 or FM 4470 are described and listed in FM Approvals' online approval directory, RoofNav.

Roof systems' wind-resistance capacities that have been tested and currently are classified by UL in accordance with UL 580 or UL 1897 are listed in UL's Roofing Materials & Systems Directory and online certifications directory.

Also, roof system designers should consult roof system manufacturers for roof system design, specification and installation information that may not be described by FM Approvals or UL.

When evaluating and comparing wind-resistance capacities among different roof systems, I encourage roofing professionals to make comparisons using similar wind-resistance capacity determination test methods. For some identical roof systems, wind-resistance capacity results sometimes vary significantly between test methods (see "Do wind-resistance capacity test methods yield similar results?" page 50).

Also, for hurricane-prone regions, I encourage designers to consider specifying roof systems that have been tested and are classified based on long-duration test methods, such as UL 580. Long-duration test methods provide for test conditions that are more representative of the duration of high winds during actual hurricane conditions than short-duration test methods (such as UL 1897, FM 4450, FM 4470 and FM 4474). ASCE 7-05 defines hurricane-prone regions as areas in the U.S. and its territories along the Atlantic Ocean and Gulf of Mexico where the basic wind speed is greater than 90 mph and Hawaii, Puerto Rico, Guam, Virgin Islands and American Samoa.

The fundamental approach

Roof system designers should use ASCE 7-05 to determine design wind loads on roof systems on a project-specific basis. By applying an appropriate safety factor to design wind loads, designers can determine roof systems' minimum recommended design wind resistances. For many common building types, NRCA's online wind-load application, www.roofwinddesigner.com, can be used to help determine these values.

From these values, roof system designers should select and specify roof systems with wind-resistance capacities equal to or greater than minimum recommended design wind resistances. UL's Roofing Materials & Systems Directory and online certifications directory and FM Approval's RoofNav application can be used to help identify such systems.

In most instances, roof system designers should be able to perform the calculations and analyses necessary to provide wind-resistant and code-complaint low-slope membrane roof systems. In situations where this determination is more complex, a roofing professional experienced in wind-resistant design or licensed design professional should be consulted.

Mark S. Graham is NRCA's associate executive director of technical services.

Do wind-resistance capacity test methods yield similar results?

Although the International Building Code, 2006 Edition, and NFPA 5000: Building Construction and Safety Code allow for testing wind-resistance capacities for low-slope membrane roof systems by any of four test methods, do not assume each of these four test methods will yield identical results. Because the test apparatuses and procedures used in FM 4450, "Approval Standard for Class 1 Insulated Steel Roof Decks"; FM 4470, "Approval Standard for Class 1 Roof Covers"; UL 580, "Tests for Uplift Resistance of Roof Assemblies"; and UL 1897, "Uplift Tests for Roof Covering Systems," differ noticeably, differing wind-resistance capacity results should be anticipated.

In 2001, NRCA conducted wind-resistance capacity testing according to UL 580 and UL 1897 on identical copper architectural metal panel roof system specimens at a recognized testing laboratory. The test conducted according to UL 580 resulted in a wind-resistance capacity of 90 pounds per square foot (UL Class 90). The test conducted according to UL 1897 resulted in a wind-resistance capacity of 165 pounds per square foot, about 80 percent higher than UL 580's result. The tested roof systems' failure mechanisms were similar in both tests.

Although some differences in the tests' results are not unexpected because of differing test durations and pressure cycles, the magnitude of the difference between the results is surprising. NRCA attributes the difference to UL 580's longer test duration and alternating pressure cycling and how this particular roof system type tested responded to the different conditions. (For additional information about this test, see "NRCA analyzes and tests metal," May 2003 issue, page 28.)

NRCA has not performed correlative testing between UL 580 and UL 1897 and FM 4450 or FM 4470. However, for many roof system types, NRCA anticipates FM 4450's and FM 4470's results to be equal or relatively close to the results from UL 1897. This is because FM 4450 and UL 1897 have similar test durations and relatively similar test pressure conditions.