Earlier this year, NRCA conducted limited testing of polymer-modified bitumen sheet products, which serves as a follow-up to similar testing NRCA conducted during 2011 and 2015. The purpose of the testing is to determine whether polymer-modified bitumen sheet products are being manufactured in compliance with applicable product standards and whether compliance has improved since the previous testing.

Previous testing

In 2011, NRCA tested 16 polymer-modified bitumen sheet products and found 10 of the products did not comply with one or more of the physical property requirements provided for in the applicable product standards. Low-temperature flexibility and granule loss were the physical properties where noncompliance was identified.

In 2015, NRCA tested 13 polymer-modified bitumen sheet products and found four of the products did not comply with one or more of the physical property requirements provided for in the applicable product standards. Again, low-temperature flexibility and granule loss were the physical properties where noncompliance was identified.

Because polymer-modified bitumen sheet products’ compliance with applicable ASTM International product standards is a building code requirement, our noncompliance findings were of specific concern.

Latest testing

NRCA obtained full rolls of 18 new (uninstalled) polymer-modified bitumen sheet products from 10 manufacturers; 11 products were SBS polymer-modified bitumen, and seven were APP polymer-modified bitumen. The samples were obtained from NRCA contractor members and members of the Midwest Roofing Contractors Association’s Technical and Research Committee from material stock they had on hand.

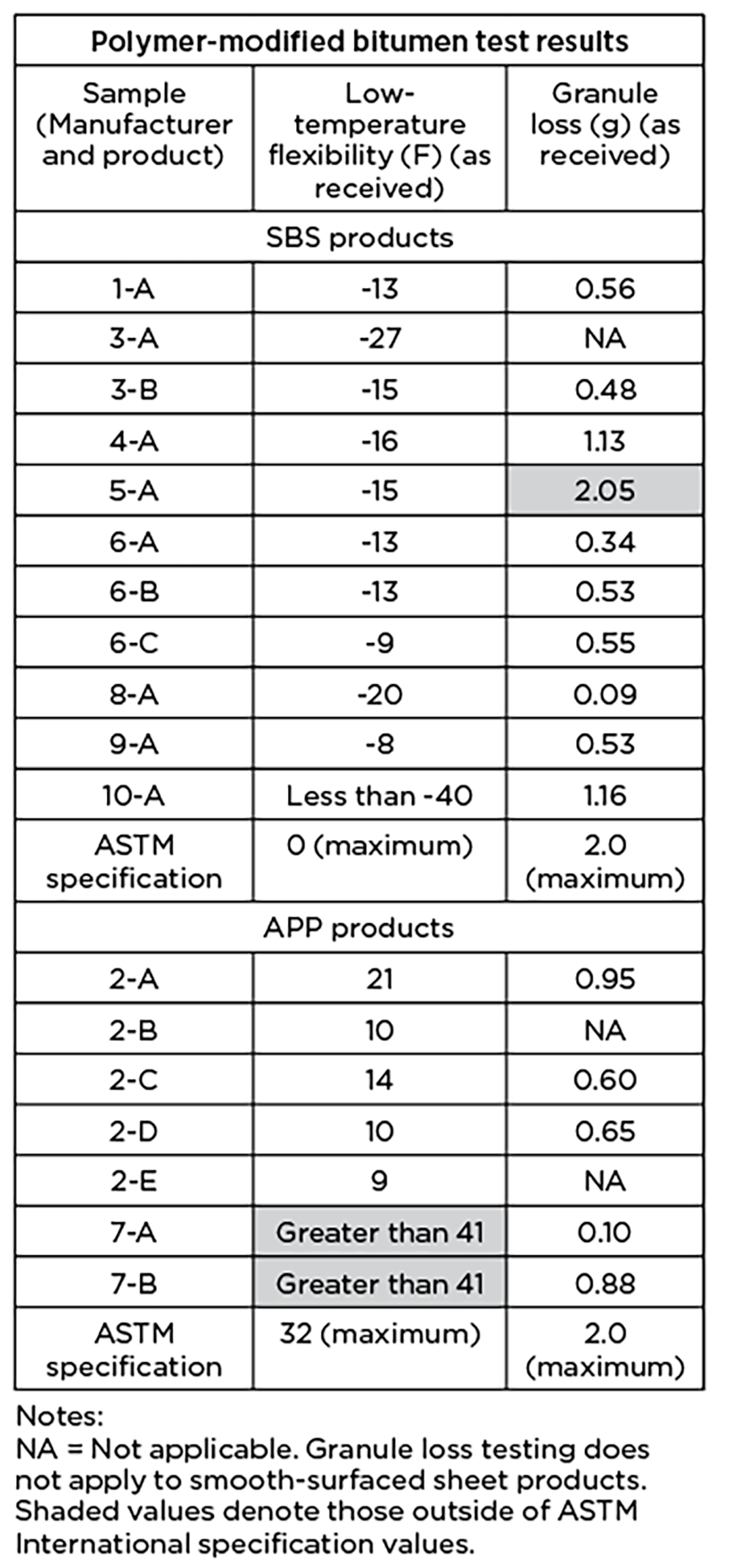

Product specimens were tested as received for low-temperature flexibility and granule loss according to the applicable ASTM International test methods. Test results are shown in the figure.

The ASTM International product standards for polymer-modified bitumen sheet products provide for a maximum allowable low-temperature flexibility of 0 F for SBS products and 32 F for APP products. All the SBS products tested and five of the seven APP products tested complied with ASTM International’s low-temperature flexibility requirements.

ASTM International’s product standards also provide for a maximum allowable granule loss of 2 grams for SBS and APP products. All but one of the granule-surfaced SBS products tested and all the granule-surfaced APP products tested complied with ASTM International’s granule loss requirement.

Recommendations

NRCA recognizes the single-roll testing of multiple products used in this limited testing program may not be statistically representative of all polymer-modified bitumen sheet products being manufactured, but the latest test results show a notable overall improvement in compliance.

However, the tested low-temperature flexibility values for Samples 7-A and 7-B are particularly concerning given the magnitude of the differences between ASTM International’s maximum allowable values and both of these samples; though they are different products, they are from the same manufacturer. There are several reasons why specific products may not achieve adequate low-temperature flexibility values, including inadequate polymer content and dispersion during manufacturing. Variability in or a lack of adequate quality control during manufacturing likely are exacerbating factors.

To address this concern, NRCA suggests designers, specifiers and purchasers of polymer-modified bitumen sheet products seek out manufacturers and products with third-party certifications of compliance with applicable ASTM International product standards. Similar third-party certifications are common among asphalt shingle products, and several manufacturers have third-party certifications for their polymer-modified bitumen sheet products. A UL product certification is one example of a third-party certification of compliance. Also, products recognized by ICC-ES or Miami-Dade County typically incorporate third-party certifications of compliance.

Polymer-modified bitumen sheet product manufacturers having third-party certifications of compliance typically will make these certifications readily known and accessible. NRCA encourages other manufacturers to do so.

Additional information about polymer-modified bitumen sheet products is provided in Chapter 5-Roof Membranes of The NRCA Roofing Manual: Membrane Roof Systems—2019.

Mark S. Graham is NRCA's vice president of technical services.

@MarkGrahamNRCA

Information about the ASTM International test method and product standards applicable to polymer-modified bitumen sheet products is provided in “Specifying modified bitumen sheet products.”

This column is part of Research + Tech. Click here to read additional stories from this section.