During recent years, there has been debate in the U.S. roofing industry regarding the appropriateness and applicability of tear-strength testing for evaluating fiberglass-reinforced asphalt strip shingles. This debate usually involves shingle manufacturers who indicate tear-strength testing is an unreliable, inadequate predictor of shingle performance and users of asphalt shingles who contend it is one of the only quantifiable measures available for assessing asphalt shingles.

In 2001, NRCA began a limited research project where the tear-strength values of a number of asphalt shingles were tested in an as-received condition and after condensation conditioning, heat aging and five years. The research results provide some useful information for assessing the appropriateness and applicability of tear-strength testing for fiberglass-reinforced asphalt strip shingles.

NRCA research

In 2001, NRCA obtained samples of 15 fiberglass-reinforced asphalt strip shingle products represented to be warranted by manufacturers for 25 years and comply with ASTM D3462, "Standard Specification for Asphalt Shingles Made from Glass Felt and Surfaced with Mineral Granules." The products were procured from throughout the U.S. through normal distribution sources by NRCA technical committee members. Product sample lots consisted of a minimum of five bundles of asphalt shingles in their original packaging for each product analyzed.

Asphalt shingle products from eight manufacturers were included in this research. In several instances, multiple products from the same manufacturer were included; these are identified by similar letter designations in the test data.

Also, in many instances, products from the same manufacturer that have the same product name but were manufactured in different plants were included. For example, samples C-1, C-2 and C-3 are from the same manufacturer and have the same product name but were manufactured in different plants. Similarly, samples F-1, F-2 and F-3 are from the same manufacturer and have the same product name but were manufactured in different plants.

Testing

Tear-strength tests were conducted on the asphalt shingle products in four conditions: as received, after condensation conditioning, after heat aging and after five years.

As-received testing was conducted on asphalt shingle specimens after 24 hours of conditioning at laboratory conditions (73 F plus or minus four degrees and 50 percent relative humidity plus or minus 5 percent). This standardized conditioning is intended to equalize product samples that may have encountered variances in temperature and wetness during shipment and initial storage. The as-received testing is intended to represent new products.

During the condensation conditioning test, specimens were subjected to an alternating cycle of wetting the asphalt shingle specimens by heating a water bath in a test chamber to 122 F for four hours and for an additional four hours allowing the water bath to cool to standard room conditions (73 F plus or minus four degrees). This condensation conditioning is intended to simulate a humid, wet environment. At the end of 30 days of cycling, the specimens' tear strengths were tested.

The heat-aged samples were subjected to 158 F plus or minus five degrees in a convection oven chamber for 30 days to simulate a hot, dry environment before being tested.

The five-year aging test consisted of storing the samples for about five years in a laboratory maintained at standard laboratory conditions meant to simulate aging in an optimum environment. At the end of the storage period, the specimens' tear strengths were tested.

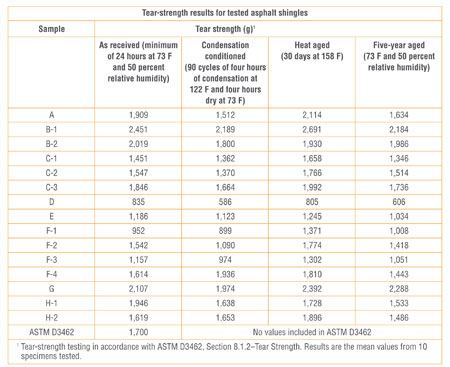

Figure 1: Tear-strength results for asphalt shingles tested by NRCA

Tear-strength testing was conducted using an Elmendorf Tear Strength Tester in accordance with ASTM D3462, Section 8.1.2-Tear Strength. For each conditioning period, 10 specimens of each product sample were tested.

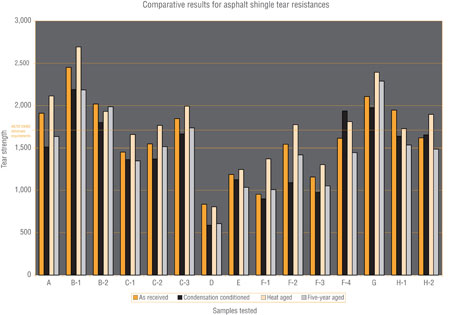

Figure 2: A comparison of tear-strength test results for asphalt shingles

The test results are provided in Figures 1 and 2. The results presented are the mean value from each of 10 specimens tested.

Analyzing the results

Review of the tear-strength testing results reveals only six of the 15 shingle samples tested have as-received tear-strength values that meet or exceed the 1,700-g minimum requirement contained in ASTM D3462 for new asphalt shingle products.

Of the shingle samples that do not meet the minimum requirement, several samples have as-received tear-strength values that are relatively close to ASTM D3462's minimum requirement. For example, the values for Sample F-4 (1,614 g) and Sample H-2 (1,619 g) are close to ASTM D3462's 1,700-g minimum threshold. These values fall close enough to the 1,700-g minimum threshold that, when considering the recognized variability for the tear-strength test method, these samples could be considered as complying with ASTM D3462.

However, for other samples, their as-received tear-strength values clearly are well below the minimum threshold. For example, the as-received tear-strength values for Sample D (835 g) and Sample F-1 (952 g) are significantly lower than the 1,700-g minimum threshold.

For the condensation conditioning test, 13 of the 15 asphalt shingle samples exhibit values below their as-received tear-strength values.

Four condensation-conditioned samples exhibit tear-strength values that exceed the 1,700-g minimum requirement in ASTM D3462. However, it is important to realize ASTM D3462 does not include a test requirement or minimum value for tear strength after condensation conditioning.

Review of the heat-aged samples reveals 12 of the 15 asphalt shingle samples exhibit tear-strength values above the as-received tear-strength values.

Comparing the heat-aged samples' values to the condensation-conditioned samples' values reveals 14 of the 15 asphalt shingles exhibit tear-strength values for the heat-aged samples greater than those for the condensation-conditioned samples. For most samples, the differences between the condensation-conditioned values and higher heat-aged values are notable.

Ten of the 15 heat-aged samples exhibit tear-strength values that meet the 1,700-g minimum requirement contained in ASTM D3462. Interestingly, more samples that were heat-aged meet the minimum requirements than those in as-received conditions. However, it is important to realize ASTM D3462 does not include a test requirement or minimum value for tear strength after condensation conditioning.

Thirteen of the 15 samples tested after five years have tear-strength values below the as-received values. And seven of the 15 five-year heat-aged samples have tear- strength values below condensation-conditioned values.

Comparing the five-year samples to the heat-aged samples reveals all 15 five-year heat-aged samples have tear-strength values below heat-aged values.

Four of the 15 five-year samples exhibit tear-strength values that meet the 1,700-g minimum requirement contained in ASTM D3462. However, ASTM D3462 does not include a test requirement or minimum value for tear strength after five-year aging.

What is known

NRCA's testing of fiberglass-reinforced asphalt strip shingles illustrates the dynamic nature of asphalt shingles' tear-strength values in as-received conditions and after condensation conditioning, heat aging and five years.

NRCA's testing shows moisture accumulation on fiberglass-reinforced asphalt shingles—such as was simulated by its condensation conditioning—generally results in tear-strength values trending downward from their as-received values.

The testing also shows limited heat aging of fiberglass-reinforced asphalt shingles, which effectively dries the shingles, generally results in tear-strength values rebounding from the condensation-conditioned values to their as-received values or even higher.

As expected, the five-year tear-strength values generally are lower than the as-received and heat-aged values.

You should use this information if you are testing new, uninstalled fiberglass-reinforced asphalt shingles for compliance with ASTM D3462 or assessing the tear strengths of already installed shingles. In either situation, heat age the test specimens before tear-strength testing. The heat-aging conditions NRCA implemented were used for research purposes. Other temperatures and a shorter duration may be more appropriate for other testing purposes.

Mark S. Graham is NRCA's associate executive director of technical services.