In 1913, Oskar von Miller, a German engineer, commissioned Carl Zeiss Works, a manufacturer of optical systems, to design a mechanism that projects an image of celestial bodies onto a dome. The invention was achieved by Walther Bauersfeld, and the first planetarium debuted in Munich in 1923. By 1929, there were 15 planetariums in Europe.

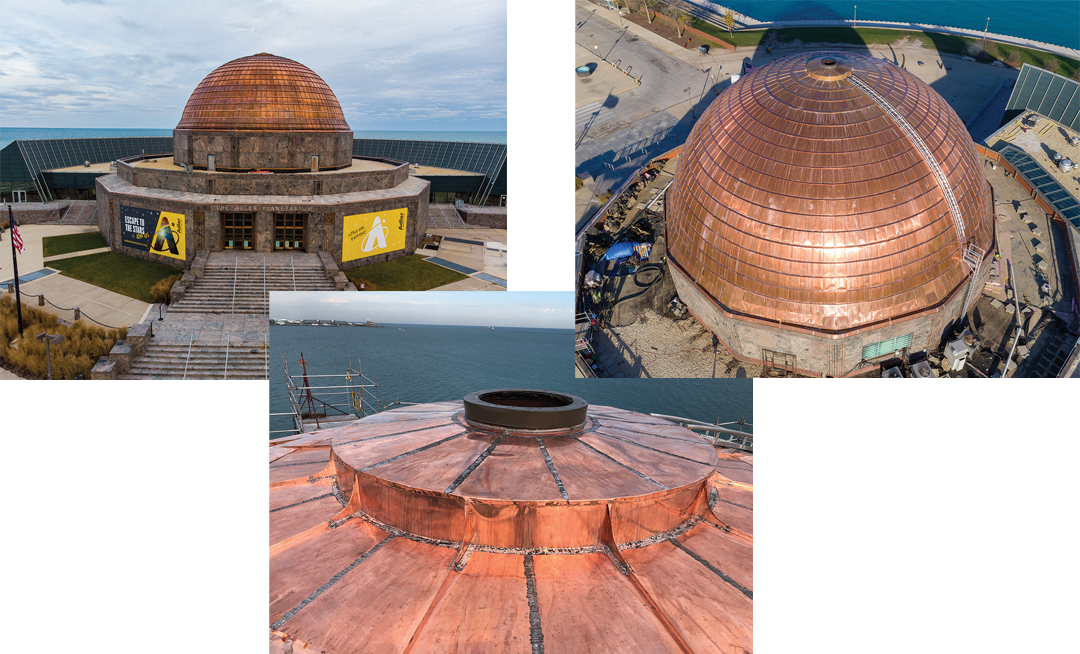

Max Adler, a retired former executive from Sears, Roebuck & Co., Chicago, visited the original planetarium in Germany with his cousin, architect Ernest Grunsfeld Jr. Adler commissioned Grunsfeld to design a planetarium for Chicago, and on May 12, 1930, Adler’s birthday, the first planetarium in the U.S. opened on Northerly Island. The Chicago chapter of The American Institute of Architects awarded Grunsfeld a gold medal for his design.

Decades later, the lead-coated copper roof system on Adler Planetarium’s dome began to erode, exposing raw copper that patinaed green. During 2021, A-1 Roofing Co., Elk Grove Village, Ill., and Hutchinson Design Group Ltd., Barrington, Ill., teamed up to restore the Chicago landmark.

Design and prep

In April 2021, the teams began work on Adler Planetarium. The project originally was set to begin in spring 2020 but was delayed because of the COVID-19 pandemic.

“We all revisited the project the following year, and it was determined on-site work would begin in May 2021,” says Jeremy Schnizlein, project manager for A-1 Roofing. “With the museum closed to the public all of 2021, deliveries and hoisting the material would be much easier.”

Hutchinson Design Group designed the dome’s new copper roof system, prepared plans and spec documents, reviewed submittals and observed construction. The teams worked closely with Gilco Scaffolding Co., Chicago, to devise a solution to access the dome safely. A five-level scaffolding setup was designed to rest on the dome and engineered to withstand winds off Lake Michigan.

“The planetarium is next to Lake Michigan where it is exposed to the elements and has its own unique weather,” Schnizlein says. “Wind, rain and flies always were a challenge. We secured all material to withstand whatever surprises were going to come any given day.”

The dome

Once scaffolding was erected, a crew from M&E Construction Co., Elgin, Ill., helped remove the existing copper, underlayment and cork insulation from the 10,000-square-foot dome. It was a slow process as it was imperative the dome’s interior remain dry.

“The dome tear-off was an extremely complicated part of the roofing project,” Schnizlein says. “We started at the bottom and worked up, removing each section down to the concrete. We took great care to keep the roof watertight at the end of each day.”

The crew installed 2- by 2-inch wood battens on the concrete roof deck and added high-density EPS insulation in between the battens followed by two layers of 3/8-inch-thick marine-grade plywood bended to the dome’s radius. The plywood was glued and screwed to the battens. This involved a great deal of measuring and cutting as a result of the rounded surface.

Next, team members applied GRACE ICE & WATER SHIELD® HT self-adhering underlayment and nailed SOPRALENE® 180 polymer-modified bitumen underlayment to the plywood. Workers then placed red rosin paper to prevent the 20-ounce copper panels from adhering to the underlayment.

Tapered standing-seam, loose- and flat-lock copper roof panels were fabricated and installed by Progressive Dynamics Inc., Streamwood, Ill. Every row of panels incorporated a variety of sizes and shapes to conform to the radial nature of the dome and match the original.

“The goal was to replicate the original aesthetic appearance,” explains Tom Hutchinson, AIA, FIIBEC, RRC, principal at Hutchinson Design Group. “The dome base is designed as a dodecagon (12 sides). Each of the corners was set as an expansion joint location that continued to the dome cap. In between each expansion joint are nine vertical sections tapering up to the top of the dome. The dome elevation was horizontally divided into 16 equal sections from the base up to the top of the dome.

“Each roof panel was designed and fabricated in a trapezoidal shape with a concave curve; the sides had a flange for a lock seam and the ends (top and bottom) had returns for a loose-lock seam. With the wind off the lake, we wouldn’t have been able to use larger, full radial panels for fear of losing some during and after installation.”

High winds and crashing waves made installing the panels difficult.

“Getting the control lines to keep the panels in line was fun and a small challenge for some on our team,” Hutchinson says. “The younger workers on the crew only had experience with lasers to create level horizontal lines, which didn’t work on a large radial dome. The installation team had to revert to what was used 40 years ago—a water-level line. It’s a wonderful feeling to pass down some old techniques to younger generations.”

Low-slope and gutters

At the bottom of the dome is a 30,000-square-foot low-slope roof area covered in ballast. The A-1 Roofing team removed the old ballast and existing insulation and cleaned the surface of the existing hot rubberized asphalt waterproofing. Next, crew members loosely laid 45-mil FleeceBACK EPDM, placed a drainage mat on the membrane and laid down extruded polystyrene insulation followed by concrete pavers and light-colored ballast.

New roof drains that direct rainwater to an interior copper gutter system were installed around the dome’s base. This work involved constructing scaffolding inside the dome’s attic to access the drains to tie into the gutter system.

In addition, at the top of the dome are cellular and TV antennae. The original access structure to the dome’s top was made of brass bars affixed to the dome’s deck. The spacing was wide and a challenge to climb, so the teams added a custom-designed radial aluminum ladder with a rail for fall protection that was attached to the brass bars.

An icon restored

The teams completed the Adler Planetarium project in December 2021 before snow arrived. More than 14,000 pounds of copper were used to restore the high-profile dome.

“It was rewarding recreating a 100-year icon,” Schnizlein says. “I never thought I would one day stand on the top of the dome of Adler Planetarium. It was rewarding to help on a project that is a well-known part of Chicago architecture as well as a place I have been visiting since I was a kid.”

For its work on Adler Planetarium, Hutchinson Design Group was awarded a 2022 North American Copper in Architecture Award from the Copper Development Association.

PROJECT NAME: Adler Planetarium

PROJECT LOCATION: Chicago

PROJECT DURATION: April-December 2021

ROOF CONSULTANT: Hutchinson Design Group Ltd., Barrington, Ill.

ARCHITECT: Wight & Company, Darien, Ill.

ROOFING CONTRACTORS: A-1 Roofing Co., Elk Grove Village, Ill.; M&E Construction Inc., Elgin, Ill.; Progressive Dynamics Inc., Streamwood, Ill.

ROOF SYSTEM TYPES: Copper and EPDM

ROOFING MANUFACTURERS: Carlisle SynTec Systems, a division of Carlisle Construction Materials, Carlisle, Pa.; GCP Applied Technologies Inc., New Haven, Conn.; Revere Copper Products Inc., Rome, N.Y.

CHRYSTINE ELLE HANUS is Professional Roofing’s associate editor and an NRCA director of communications.