Many roof assemblies are constructed with mechanically attached single-ply membrane roof systems over rigid board roof insulation over steel roof decks supported by open web steel joists. Although this particular roof assembly is prevalent, there continues to be some confusion with regard to proper membrane orientation relative to the direction of steel deck flutes. This confusion with orientation sometimes can lead to underestimating wind-uplift design loads.

Wind resistance

For a mechanically attached single-ply membrane roof system over rigid board roof insulation over a steel deck, the steel deck typically is welded or mechanically fastened to the steel joists.

However, wind-uplift resistance with regard to the steel deck and joists must be considered when designing a single-ply roof membrane system. To understand wind uplift, wind-load fundamentals must be explained. When there is no wind, air pressure on the topside surface of a roof is the same as that on the underside of a roof. In this case, a roof assembly is in a state of equilibrium when the wind speed is zero. However, as soon as wind moves across the roof, it decreases the air pressure on the topside surface. At the same time, the air pressure on the underside of the roof remains the same. Because the air pressure is greater on the inside of the building, it exerts a force on the roof assembly that causes it to lift up, which is why this phenomenon is called "wind uplift." The load imposed on the roof system from this difference in air pressure is called the uplift load.

When an uplift load is imposed on a roof assembly, it follows a load path that should lead to the structural support elements of a building. In the case of a mechanically attached single-ply membrane roof system, the uplift load on the membrane transfers to the fasteners, which, in turn, transmits the load to the steel deck. Next, the load transfers from the steel deck to the open web steel joists through the welds or fasteners that attach the steel deck to the joists.

The amount of load a row of fasteners resists depends on the tributary area, which is the area that contributes to the loading of a specific building or structural element. In the case of a row of fasteners, the tributary area extends half the distance to the row of fasteners on each side. Simply put, the tributary area for a row of fasteners is a function of the distance between the rows of fasteners.

Clearing up the confusion

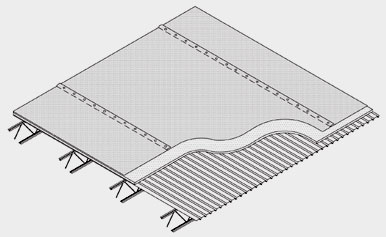

One concern with regard to a mechanically attached single-ply roof assembly construction is the overstressing of a steel deck's attachment to steel joists. Figure 1 illustrates a single-ply roof membrane installation where this condition most likely will occur. The figure shows the membrane sheets oriented parallel to the deck flutes and the fasteners located along the length of a single flange in the steel deck. In this case, the wind load from the tributary area is transferred to a row of membrane fasteners in a single deck flange. The load then is transferred to the deck attachments, which, in this case, are one weld or two welds or fasteners at each joist. In most circumstances, one weld or two welds or fasteners are not capable of resisting the expected uplift load.

Figure 1: A mechanically attached single-ply membrane roof system

with the membrane installed parallel to flutes of steel deck

It is important to note this concern not only pertains to geographic areas subject to high winds, such as hurricane regions, but it also applies to areas with moderate wind speeds. Additionally, the use of wider membrane sheets, such as those wider than 7 feet (2 m), greatly can increase the potential to overstress a steel deck's attachments.

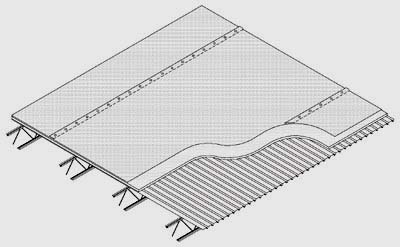

To avoid overstressing steel deck attachments, it is recommended the long dimension of membrane sheets be placed perpendicular to the ribs of the steel deck as shown in Figure 2. The membrane fasteners then are installed across the steel deck in the top flanges. In this scenario, the uplift load is distributed across the steel deck flanges instead of along a single flange. Consequently, the load transfers to a row of welds or fasteners at the steel joists.

Figure 2: To avoid overstressing steel deck attachments, it is

recommended the long dimension of membrane sheets be placed

perpendicular to the ribs of the steel deck.

However, the uplift load for a single row of fasteners isn't distributed over a series of joists as shown in Figure 1. Depending on the membrane sheet width and joist spacing, a majority of the load may only transfer to one joist or two joists. If fastener row spacing can be matched to joist spacing, each row of fasteners will distribute load to two joists. In any case, the joists' attachments to the vertical structural elements, such as walls or columns, should be designed to accommodate this loading condition.

Another consideration is the use of steel decks with yield strengths of 80 ksi (550 MPa) or higher because they typically provide greater fastener withdrawal-resistance values. Some of FM Global's approvals require such decks for 10-foot- to 12-foot- (3-m- to 3.7-m-) wide membrane sheets. (For more information about these types of steel roof decks and their designations, refer to "Differences among roof decks," October 2001 issue, page 80.)

Sources of information

Membrane orientation is an issue that sometimes is overlooked by designers. For instance, you will not see it addressed in any of the three model building codes or the International Building Code. One organization that provides information is FM Global. FM Global's Property Loss Prevention Data Sheet 1-29—Above Deck Roof Components recommends fastener rows be installed perpendicular to steel deck ribs. Underwriters Laboratories Inc. appears to be silent on this issue.

NRCA performed a limited review of some major single-ply membrane manufacturers' literature to see whether this issue is addressed in installation recommendations. NRCA found Genflex Roofing Systems, Maumee, Ohio, and Sarnafil Inc., Canton, Mass., mention membrane/fastener orientation with respect to steel decks in their literature.

NRCA encourages manufacturers to provide more detailed guidelines regarding the attachment requirements for mechanically fastened single-ply roof systems and incorporate this information in design and installation recommendations. Roof system designers should include installation information in their drawings and specifications, as well.

Joan P. Crowe is an NRCA manager of technical services.