NRCA has conducted limited testing of a moisture vapor reduction admixture intended to minimize a concrete roof deck’s ability to pass and release moisture vapor. Some background and an overview of NRCA’s testing and results follow.

What’s an MVRA?

Concrete admixtures intended as MVRAs are specific chemicals added during concrete’s batching and mixing to provide an additional chemical reaction during the concrete’s hydration and curing process. MVRAs use the concrete mix’s excess water and chlorides to create a calcium silicate hydrate gel within the concrete. The gel is said to fill the small pores and capillary openings in curing concrete, minimizing the concrete’s ability to pass and release moisture vapor. The gel is intended to be permanent and integral throughout the concrete thickness.

MVRAs are available from numerous suppliers and typically added to a concrete mix at the concrete batch plant separately from any other admixtures. Some MVRA suppliers permit their MVRAs to be added to concrete mixers at job sites provided the concrete mixer’s drum is rotated for a supplier’s recommended minimum amount of time after dosage and before concrete discharge and placement. Recommended MVRA dosages vary somewhat between suppliers but generally range from about 10 to 14 ounces per 100 pounds of cementitious material.

MVRAs reportedly have been used successfully to address moisture release affecting floor coverings over concrete slabs on grade and at intermediate floor levels.

Several suppliers also are promoting use of their MVRA products for concrete roof decks to address the roofing industry’s concerns with moisture release. However, their product literature, including product testing and data, show little to no applicability to roof decks.

For example, several manufacturers cite ASTM D5084, “Standard Test Methods for Measurement of Hydraulic Conductivity of Saturated Porous Materials Using a Flexible Wall Permeameter,” as the basis for their water vapor transmission and permeability testing. This test applies to fully saturated (containing no air) soil and rock at a limited temperature range—conditions similar to below-grade applications—with little to no relevance to roof assembly components.

NRCA testing

NRCA obtained core specimens of newly poured, cast-in-place roof decks from a building project under construction. A unique aspect of this particular project is it had multiple concrete roof decks areas—several with an MVRA and one without an MVRA. The concrete mix design was reported to be similar for all the concrete roof decks with the MVRA being the known variable.

NRCA submitted the concrete core specimens to RDH Building Science Laboratories in Waterloo, Ontario, for laboratory testing and analysis. RDH Building Science Laboratories is widely recognized for its building science and laboratory testing expertise.

The concrete core specimens were cut into approximately 1-inch-thick slices and conditioned (dried). Testing was conducted using ASTM E96, “Standard Test Methods for Water Vapor Transmission of Materials.” ASTM E96 is the standard method for determining water vapor transmission of building materials. ASTM E96 also is referenced in the International Building Code® as the basis for determining whether a building material is vapor-permeable or serves as a vapor retarder.

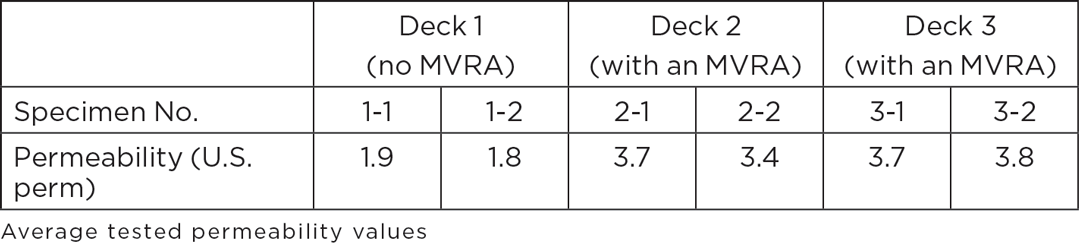

The results of the ASTM E96 testing are shown in the figure.

Review of the test data shows average tested values for the non-MVRA specimens to be generally consistent with previous NRCA testing of concrete specimens of a similar cured age.

The test data for the MVRA specimens shows permeability values greater than those of the non-MVRA specimens; this indicates the MVRA specimens are more “vapor open” than the non-MVRA specimens. These test results contradict claims an MVRA minimizes concrete’s ability to pass and release moisture vapor.

The data presented applies specifically to the specimens tested at their cured age and may not necessarily apply to all concrete mix designs and concrete roof decks.

NRCA’s recommendations

Based on its testing, NRCA finds the use of an MVRA provides no measurable benefit in a concrete roof deck’s ability to minimize the passage and release of moisture vapor.

NRCA maintains its previous recommendation: Designers should specify a high-bond strength vapor retarder be adhered directly to concrete roof decks in new construction situations. This recommendation also applies to concrete roof decks where an MVRA is used. For reroofing situations where an existing roof deck shows evidence of moisture-related problems, a high-bond strength vapor retarder also should be adhered directly to the deck. When a vapor retarder is used, roof system designs using mechanical fasteners penetrating the vapor retarder should be avoided.

Additional information about concrete roof decks is contained in Chapter 2-Roof Decks of The NRCA Roofing Manual: Membrane Roof Systems—2019. NRCA members can download the manual for free at shop.nrca.net.

Mark S. Graham is NRCA's vice president of technical services.

@MarkGrahamNRCA

For additional information about NRCA’s previous permeability testing, see “The quest for dryness.”

This column is part of Research + Tech. Click here to read additional stories from this section.