Roofing contractors have been installing roof systems over new concrete roof decks for decades. In the past, contractors and designers gave little thought to moisture in concrete decks; the only concern was how well a roofing material could adhere to a concrete surface. This was the norm through the 1990s and into this century. However, at the turn of the century, more claims by building owners of roof system failure caused by concrete deck-sourced moisture began to emerge. Photo 1 shows the result of a roof system unknowingly installed over a moisture-laden concrete deck.

Photo 1: This roof system was installed over a lightweight structural concrete deck in the upper Midwest. The roof had only been in place for a matter of months before wind delaminated the moisture-weakened polyisocyanurate facer at the membrane level. Small amounts of condensed moisture are visible on the concrete surface. |

The problem quietly simmered for about a decade. Then, the issue was put in front of the roofing industry by several papers published for the 2011 International Roofing Symposium, by the Midwest Roofing Contractors Association and NRCA. The papers focused on extra moisture in the aggregates used in lightweight structural concrete. But these papers and others that followed lacked directions or solutions for how to assess a concrete deck, what moisture levels in concrete are too high and what to do if they are too high.

Why now?

An innocent yet weighty question was asked during the 2017 Chicago Roofing Contractors Association (CRCA) trade show: "We have been roofing over concrete decks for a long time. Why is this happening now?"

The answer is multifaceted, and it relates to the roofing materials the industry uses, specifically the insulation, adhesives and membranes.

The roofing industry is using a great deal of ASTM C1289 Type II, Class 1 polyisocyanurate, which is faced with reinforced cellulosic mat facers. Colloquially known as "paper-faced iso," this product typically works well unless it is exposed to moisture.

Decades ago, there were two choices for adhesive: coal tar or asphalt. Currently, there is a plethora of adhesive choices, including foams, volatile organic compound- (VOC-) based, low VOC, water-based and others. Some adhesives have proved to be more resistant to high moisture levels than others.

The issue with roof membranes has not been so much with membrane types but rather color. Specifically, cool roofs and their high solar reflectivity, which leaves them operating at lower temperatures. Consequently, roofs with lower membrane temperatures are less able to move moisture away and potentially out of a roof system.

Another complicating factor is compressed construction schedules. Any roofing contractor who has worked on new construction knows general contractors are demanding roof systems be installed earlier and earlier in the construction schedule. Our firm has had reports of general contractors demanding roof system installation as little as three days after concrete has been poured—a truly insufferable situation.

These issues combine to explain why we are seeing more moisture problems in roof systems related to concrete decks.

Current testing

Many moisture testing methods available for concrete have been around for decades. The flooring industry has done a great deal of research into these methods and their viability. Flooring industry research has shown some of these tests to be rather unreliable predictors, and most of them generally have been moved to obsolescence; yet they remain in many roofing industry boilerplate and legacy specifications.

The spot test

When you use bitumen (coal tar or asphalt) to adhere insulation, you can conduct a spot test. To do so, heat the bitumen to application temperature and pour about a 1- to 3-foot diameter area of hot bitumen on the concrete. If the bitumen sizzles and creates pinholes (from super-heated water vapor) or a spud bar can pry cooled bitumen from the concrete, the concrete is not ready to receive a roof system. The spot test is subjective and field-improvised. Admittedly, it has served the roofing industry for decades but should be considered a last resort.

ASTM D4263

ASTM D4263, "Standard Test Method for Indicating Moisture in Concrete by the Plastic Sheet Method," is qualitative in nature. A plastic sheet is affixed to the concrete surface for 24 hours, and pass/fail is determined based on whether moisture can be seen between the concrete and plastic film. However, any moisture detected is local to the concrete's surface. Additionally, the test can be heavily influenced by weather conditions. This test generally is considered unreliable and unable to detect moisture located deep in concrete.

ASTM F1869

ASTM F1869, "Standard Test Method for Measuring Moisture Vapor Emission Rate of Concrete Subfloor Using Anhydrous Calcium Chloride," uses a small plastic dome placed over the concrete surface with a desiccant inside. The desiccant is weighed before and after exposure; from this, a moisture vapor emission rate is determined. Tests conducted by the concrete and flooring industries have shown this test only measures moisture contained within a fraction of an inch of the concrete surface, leaving the moisture deeper in the slab unmeasured. In short, the flooring industry is abandoning this test method, and similar to the plastic sheet method, the test is affected by weather. As such, it, too, should not be considered viable for concrete roof deck assessment.

Electrical resistance

Electrical resistance testing generally is not seen in North America. It is used in Europe and consists of two holes drilled in a concrete deck a specified distance apart with wire brushes inserted in each. The electrical resistance is measured between the two brushes. This resistance will vary with moisture content. Although this method will reach moisture deep in a slab, concrete experts have reported the resistance of the concrete depends on a great deal of variables other than moisture. This makes a reading from one concrete slab potentially meaningless when compared with a different concrete slab. Therefore, its use as a universal tool for the roofing industry appears limited.

Electrical impedance

Similar to electrical resistance, electrical impedance uses an electrical measurement to correlate to moisture content in concrete. There are several commercially available models from manufacturers of handheld meters. However, experience and research have shown they only measure moisture near the surface of concrete. Although these models may be suitable for determining a "surface dry" condition for concrete, they are unable to measure and/or detect moisture in the core of a slab.

ASTM F2170

ASTM F2170, "Standard Test Method for Determining Relative Humidity in Concrete Floor Slabs Using in situ Probes," involves drilling into concrete and placing a sensor at a prescribed depth. The sensor returns temperature and humidity readings after remaining in place for 72 hours. The flooring industry has widely adopted this method as part of manufacturer requirements before a flooring system is installed.

This methodology has shown some promise for the roofing industry. However, obtaining appropriate readings generally is confounded by ambient weather conditions. Specifically, the test is specified to be run at room temperatures. There are seldom room temperature conditions on a roof deck. Additionally, research has shown there is a coupled system between the air being measured inside the sensor and the drilled concrete to which it is exposed. The air obeys the psychometric chart, but the exchange of moisture between the air and concrete as temperatures change appears not to. Again, this makes it difficult to use as a universal test.

However, this method still has value forensically for evaluating existing concrete roof decks. The probes, when installed under insulation, achieve room temperature or near room temperature conditions. Therefore, they can be used diagnostically to confirm, deny and quantify in-situ moisture within existing concrete roof decks.

Current research

The numerous roof system failures and concrete moisture test methods as well as lack of research data regarding moisture in concrete roof decks led NRCA; CRCA; the Canadian Roofing Contractors Association; GAF, Parsippany, N.J.; and SOPREMA® Inc., Wadsworth, Ohio, to sponsor research into this topic in 2016.

The initial research was focused on outdoor exposure of concrete slabs, concrete slabs exposed in a controlled laboratory environment, hygrothermal laboratory measurements, instrumentation trials and computer modeling. The research occurred in three phases.

Phase 1

The first phase involved SRI Consultants Inc. constructing test concrete roof slabs and preparing them for instrumentation of temperature and humidity at depth. The slabs were located at SRI Consultants' facility in Middleton, Wis. The slabs were configured for measuring and examining the following variables:

- Aggregate type (regular weight vs. lightweight)

- Surface finish (magnesium float vs. hard steel trowel)

- Rewetting (outdoor vs. laboratory)

- Drying capacity (steel form deck vs. stripped form)

- Moisture level in slabs over time

- Time required for instruments to measure moisture levels

The outdoor slabs were prepared and instrumented for a factorial experiment to evaluate the first five variables and compared against slabs prepared and maintained indoors, in a controlled laboratory environment. Numerous smaller concrete specimen pans were prepared for weekly installation of instrumentation to measure the last three variables; these specimens are outdoors and in a laboratory environment. In all, more than 200 instruments were used with the slabs during this phase. In addition to temperature and humidity measurements, a weather station recorded companion data during this phase. The station was positioned with the outdoor specimens and slabs.

Photo 2: Concrete slabs and pan specimens, both regular weight and lightweight structural concrete, in SRI Consultants’ laboratory in 2016 |

Photo 2 shows the 5- by 5-foot slabs in the lab along with smaller 1- by 1-foot pans. Photo 3 shows the slabs being prepared outdoors for exposure to weather, and Photo 4 shows the completed slabs and pans undergoing weathering.

Photo 3: Exterior concrete slabs being poured at SRI Consultants’ facility in July 2016 |

Photo 4: The poured concrete slabs and pan specimens, both regular weight and lightweight structural concrete, during outdoor weathering |

Phase 2

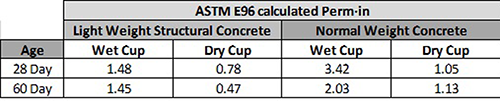

R&D Services Inc., Cookeville, Tenn., provided laboratory measurements of hygrothermal material properties for the concrete used in Phase 1. The samples were cast alongside the slabs and pans. The measured concrete values were targeted at 28 and 60 days. It is believed hygrothermal numbers for such "green" concrete have not been previously determined by others. The hygrothermal material numbers were used in Phase 3 of the work. Photo 5 shows concrete samples prepared for ASTM E96, "Standard Test Methods for Water Vapor Transmission of Materials," vapor transmission testing. Results of the ASTM E96 testing are reported in the figure.

Photo 5: Concrete specimens prepared for ASTM E96 water vapor transmission testing |

Phase 3

The hygrothermal data from Phase 2 was used with WUFI Pro software. WUFI Pro is a finite element heat and moisture transport modeling program. With this software, an experienced user can simulate the moisture movement to, from and within concrete roof decks. It also can simulate moisture movement in concrete after a roof is placed over it. If properly calibrated, validated and used, these models can be a powerful tool to analyze the moisture problems the roofing industry is experiencing.

Using the WUFI Pro software, hygrothermal simulations were designed and run, with the assistance of JustSmartSolutions, Oak Ridge, Tenn. The simulations were expanded to a matrix of roof system types and locations throughout North America.

What it means

To date, hundreds of computer simulations of moisture movement in concrete decks exposed to historical weather data have been completed. The concrete moisture levels at the end of the bare concrete deck simulation were entered into a new simulation with a hypothetical roof system installed over the concrete deck. The simulations answered several questions and raised new ones.

The specific issue of rewetting concrete was observed in the outdoor instrumenting and was predicted by the computer modeling. This concept is rather fundamental: New concrete roof decks exposed to precipitation, including dew and frost, will absorb moisture. Conversely, dry weather will allow for dry down of the new concrete deck. Therefore, the moisture levels in a new concrete deck is transient and difficult to predict by mere observation of past weather at a specific location.

For example, the simulations showed a roof system using paper-faced polyisocyanurate insulation and no vapor retarder installed over a normal regular weight concrete deck cast in July near Atlanta could be suitable for roofing 28 days after it was poured. However, this same roof deck, if cast in December, would need a vapor retarder to keep the paper facers at an acceptable moisture level to function as intended.

Repeat this simulation in Phoenix, and the concrete dries sufficiently 28 days after the pour in any given time of year. As such, in an environment like Phoenix a vapor retarder is most likely not needed.

Now, if one moves the simulation to Edmonton, Alberta, there appears to be no month during which this same roof system could be installed after 28 days without a vapor retarder. Some areas of North America provide easy answers regarding concrete decks while much of the continent seems to fall into an "it depends" category on the use of vapor retarders to protect roof systems from moisture migration out of concrete.

The simulations run to date have focused on regular weight concrete decks. A handful of simulations looked at the effects of utilizing lightweight structural concrete. Of little surprise to those familiar with the extra evaporable water available from lightweight aggregates, the results of these simulations are much worse from a moisture migration standpoint.

The research is ongoing. In 2017, more concrete decks will be cast, and roof systems will be installed over them. The 2017 research will focus on validating the Phase 3 computer modeling.

Preliminary recommendations

The simulations conducted to date answered many questions. Specifically, northern climates are at greater risk of moisture-based failure, specifically with paper polyisocyanurate facers. This occurred with normal weight concrete decks and lightweight structural concrete decks. Therefore, given the currently available research data, I recommend that unless the designer of record states otherwise in writing, a vapor retarder of less than 0.01 perm is necessary over new concrete roof decks. Note this level of vapor retarder (0.01 perm) is relatively stringent and some commonly used vapor retarders may not meet this level.

The figure shows results of ASTM E96 water vapor transmission testing. Note the lightweight structural concrete has about half of the permeability of regular weight concrete. Considering lightweight structural concrete arrives with more than twice the evaporable water of regular weight concrete, this explains why lightweight structural concrete retains moisture for so long. |

The only alternative to retarding moisture entry from a concrete roof deck into a roof system is venting the moisture vapor out of the system. To achieve this, designers essentially need to design roof assemblies as if they were roofing over lightweight insulating concrete. Numerous manufacturer and NRCA details are available and adaptable for this type of configuration. In fact, this design recently has been observed in practice and was functioning as intended—keeping the concrete moisture divorced from the roof system.

As the research progresses, more updates and recommendations will become available.

Matt Dupuis, Ph.D., P.E., is principal of SRI Consultants Inc., Middleton, Wis.