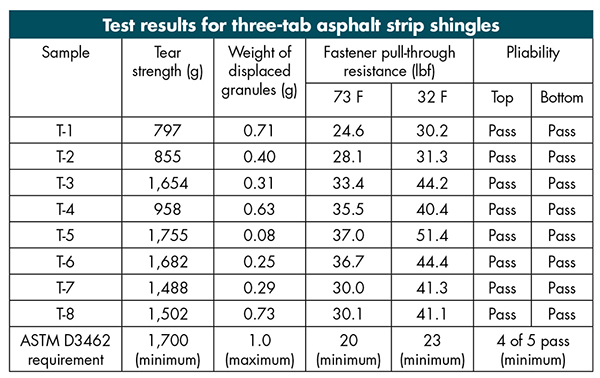

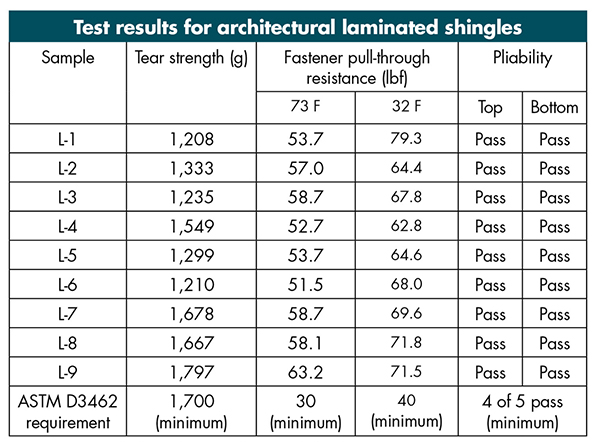

NRCA conducted limited physical property testing during 2016 on a number of samples of new (uninstalled) asphalt shingle products. The testing's goal was to determine the samples' compliance with ASTM D3462, "Standard Specification for Asphalt Shingles Made from Glass Felt and Surfaced with Mineral Granules." The results also provide a basis for comparison with previous NRCA testing.

ASTM D3462

ASTM D3462 describes methods for testing and evaluating fiberglass-reinforced asphalt shingles. It addresses materials and manufacture; physical requirements; dimensions, masses and permissible variations; workmanship, finish and appearance; sampling and test methods; inspection; rejection and resubmission; and packaging, marking and shipping.

ASTM D3462's Table 1—Physical Requirements of Asphalt Shingles Made from Glass Felt and Table 2—Masses of Asphalt Shingles Made from Glass Felt provide consensus-based minimum or maximum values for the physical requirements and masses tested.

For example, ASTM D3462's minimum tear strength value is established as 1,700 grams (g). The maximum allowable weight of displaced granules is 1.0 g. The minimum average fastener pull-through resistance is 20 pounds force (lbf) for single-layer specimens and 30 lbf for multilayer specimens when tested at 73 F ± 4 F and 23 lbf for single-layer specimens and 40 lbf for multilayer specimens when tested at 32 F ± 4 F. A minimum of four out of five specimens tested must pass the pliability test at 73 F ± 4 F in the weather-side up (top side) machine (MD) and cross machine (XMD) directions and weather-side down (bottom side) MD and XMD.

Compliance with ASTM D3462 is referenced in the International Building Code and International Residential Code as a minimum requirement for fiberglass-reinforced asphalt shingles.

The current edition of ASTM D3462 was published this year and is designated ASTM D3462-16.

Previous NRCA testing

In 2001, NRCA also conducted tests on fiberglass-reinforced asphalt shingles. Since then, other fiberglass-reinforced asphalt shingle products have been tested. Data from these test programs provide a basis for comparing results from NRCA's current test program with its previous testing.

NRCA's 2001 testing program resulted in only five of the 15 fiberglass-reinforced asphalt shingle products being found to comply with ASTM D3462's then-current requirements. Nine of the 15 shingle products tested were found to have tear strength values less than ASTM D3462's minimum requirement. Also, six of the 15 products tested failed ASTM D3462's pliability test requirement. All 15 products tested in 2001 complied with ASTM D3462's granule displacement and fastener pull-though criteria.

NRCA's latest testing

This year, NRCA obtained 17 samples of new fiberglass-reinforced asphalt shingle products. Eight product samples were three-tab strip shingles; nine products were multilayer, architectural laminated shingles.

Figure 1: Test results for three-tab asphalt strip shingles |

Product samples were procured by NRCA technical committee members from throughout the U.S. through normal distribution sources. Product samples consisted of a minimum of five bundles of asphalt shingles in their original packaging. Each product was labeled as complying with ASTM D3462.

Every U.S. manufacturer of fiberglass-reinforced asphalt shingles was represented in the NRCA testing with a minimum of two products (different brand names). One manufacturer was represented with three products.

NRCA acknowledges the sampling procedure used in the 2016 and 2001 test programs does not strictly comply with ASTM D3462's sampling requirements. Additional information regarding ASTM D3462's sampling requirements and the timing of testing of asphalt shingles is provided in "Product sampling and '… as manufactured …'" (see below).

Samples were provided to a nationally recognized testing laboratory for test specimen preparation, laboratory testing and analysis. A minimum of five specimens per sample (one specimen from each asphalt shingle bundle) were subjected to testing for tear strength, fastener pull-through resistance and pliability. Weight of displaced granules (granule loss) testing also was conducted on three-tab strip shingle samples.

Results of NRCA's 2016 testing on the three-tab strip shingles samples are shown in Figure 1; architectural laminated shingle results are shown in Figure 2.

ASTM D3462 also includes test methods that were not specifically conducted in NRCA's current testing, such as loss of volatile matter, sliding of granule surfacing, wind resistance, fire resistance, asphalt penetration and asphalt softening point testing. Asphalt penetration and asphalt softening point testing are intended to be conducted before shingle manufacturing and cannot be accurately conducted on finished asphalt shingle products. Wind- and fire-resistance testing are conducted on constructed test roof deck assemblies, not individual asphalt shingles.

Figure 2: Test results for architectural laminated shingles |

NRCA considers the limited ASTM D3462 testing conducted in its 2016 test program adequate to show some degree of differentiation among uninstalled fiberglass-reinforced asphalt shingle products.

Analyzing the results

Review of the test results shows only one of the eight three-tab strip shingle samples (Sample T-5) and one of the nine architectural laminated shingles (Sample L-9) exceeded ASTM D3462's minimum 1,700-g tear strength requirement. Two three-tab strip shingle samples (Samples T-3 and T-6) and two architectural laminated shingle samples (Samples L-7 and L-8) show tear strength values slightly less than the ASTM D3462 minimum. However, when considering the recognized variability in tear strength test method, these samples could be considered as complying with ASTM D3462's minimum tear strength requirement.

All eight three-tab strip shingles tested show granule loss values complying with ASTM D3462's 1.0 g maximum.

All 17 samples tested (the three-tab strip shingle samples and architectural laminated shingle samples) show fastener pull-through values complying with ASTM D3462's established minimum values.

Similarly, all 17 shingles samples tested show pliability test results complying with ASTM D3462's minimum requirement.

Comparing the results of NRCA's most recent asphalt shingle testing to the 2001 testing reveals some information worthy of consideration.

Tear strength values in the 2016 testing are notably lower than those from the 2001 testing. Samples' tear strength values in the current testing range from 797 g to 1,797 g (with a mean value of 1,394 g); only two of 17 samples tested exceeded ASTM D3462's 1,700-g minimum requirement. Samples' tear strength values in NRCA's 2001 testing ranged from 835 g to 2,451 g (with a mean value 1,606 g); eight of 15 samples tested exceeded ASTM D3462's minimum requirement.

Granule displacement and fastener pull-through results are nearly identical between 2001 and the current testing. All samples tested comply with the ASTM D3462 requirements for these physical properties.

Pliability test results are notably better in the 2016 testing than from NRCA's 2001 testing. All the samples in the current testing complied with ASTM D3462's four out of five passing minimum requirement while in the 2001 testing only nine of the 15 samples tested complied with ASTM D3462's requirement.

Closing thoughts

Fiberglass-reinforced asphalt shingles have a significant market share in the U.S. roofing industry and continue to perform reasonably well.

NRCA's latest testing of fiberglass-reinforced asphalt shingle products yielded some results that are cause for additional consideration.

Although all the three-tab and architectural laminated shingle product samples evaluated comply with ASTM D3462's granule displacement, fastener pull-through resistance and pliability requirements, only two of the 17 samples evaluated exceeded ASTM D3462's minimum tear strength requirement.

Some in the industry—including some asphalt shingle manufacturers—may discount this finding because the testing program does not strictly comply with ASTM D3462's product sampling and time of testing requirements. However, when comparing the notably lower current test's tear strength values with the 2001 tested values, there appears to be justifiable cause for discussion and additional consideration.

Perhaps it is time for the U.S. roofing industry to develop new criteria other than ASTM D3462's tear strength testing for evaluating and differentiating among fiberglass-reinforced asphalt shingles. When developing such new criteria, it would be useful if the methodology would correlate to actual field performance. It also would be helpful if the industry agrees a new methodology would apply not only immediately after manufacturing but also up to the time of asphalt shingle procurement, delivery to the job site and installation.

Clearly, there is expertise within the asphalt shingle industry to develop such criteria. Many of these experts already regularly attend ASTM International's Committee D08 on Roofing and Waterproofing meetings and ASTM D3462 task force meetings.

NRCA looks forward to the possibility of working constructively with asphalt shingle manufacturers, interested parties at ASTM International and other roofing professionals to develop new criteria.

Mark S. Graham is NRCA's vice president of technical services.

For more about this topic, see "Asphalt shingles' tear strengths revisited," October 2006 issue.

Product sampling and "… as manufactured …"

ASTM D3462, "Standard Specification for Asphalt Shingles Made from Glass Felt and Surfaced with Mineral Granules," provides specific requirements for sampling asphalt shingle products for testing and analysis. ASTM D3462 references ASTM D228, "Standard Test Methods for Sampling, Testing and Analysis of Asphalt Roll Roofing, Cap Sheets and Shingles Used in Roofing and Waterproofing," for sampling.

ASTM D228 directs random selection of five shingle bundles from lots of 1,000 shingle bundles or less. For lots larger than 1,000 bundles, a calculation is used to determine the minimum number of bundles to select. The random nature of ASTM D228's sample selection criteria is a key consideration. Such random selection permits a shingle bundle in a lot to have the same probability of being selected for testing. This includes, for example, the bottommost shingle bundles on a pallet.

Because the asphalt shingles used in NRCA's testing were procured by NRCA member contractors through normal distribution sources, shingle bundle procurement in strict accordance with ASTM D228's random selection criteria was not practical; it is nearly impossible.

Although the asphalt shingle selection used in NRCA's testing may not be in strict accordance with ASTM D228's requirements, NRCA considers the selection process used for the testing to be representative of asphalt shingles that may be delivered to a job site.

Also, when evaluating asphalt shingles for compliance with ASTM D3462, the standard requires asphalt shingles be tested "as manufactured."

ASTM D3462's scope indicates "… This specification is designed for the evaluation of products as manufactured. The test methods, physical requirements, and minimum masses are to be measured immediately after packaging or at a reasonable time, as agreed upon between buyer and seller, after manufacture and before installation. Physical and performance requirements after application and during in-service use of the products described herein are beyond the scope of this material specification."

Because the asphalt shingles in NRCA's test program were procured by NRCA member contractors through normal distribution sources, laboratory testing immediately after manufacturing is clearly not possible.

Although NRCA's testing may not be in strict accordance with ASTM D3462's requirements, the timing of NRCA's laboratory testing can be considered representative of the conditions (some aging and changes in temperature and humidity) asphalt shingles routinely encounter up to the time of delivery to a job site and application.

Who complied?

Only two of the 17 products evaluated in NRCA's most recent round of testing complied with the physical property requirements of ASTM D3462, "Standard Specification for Asphalt Shingles Made from Glass Felt and Surfaced with Mineral Granules."

Four other asphalt shingle products had tear strength values slightly below ASTM D3462's 1,700-g minimum requirement. Based upon the known variability in the tear strength test method's results, these four products can be considered as complying with ASTM D3462's tear strength minimum requirement and, therefore, as complying with ASTM D3462's physical property requirements evaluated in NRCA's test program.

The six products (listed alphabetically) are:

- GAF Royal Sovereign®

- Malarkey Roofing Products Dura-Seal™ AR

- Owens Corning Classic® (Midwest)

- Owens Corning Oakridge® (Midwest)

- Pabco Roofing Products Premier®

- Tamko Building Products Inc. Heritage®

When considering the results of NRCA's asphalt shingle testing, understand the values and conclusions from the testing only apply to the specific product sample specimens evaluated and the specific values only may apply at the time of testing. These results may not represent all the manufacturers' products. Asphalt shingle products from different production lots and products of the same brand names manufactured in different manufacturing plants may have differing values and compliances with ASTM D3462.

Users of asphalt shingles should consult with manufacturers and suppliers regarding specific products' compliance with ASTM D3462.