Facilities with cold interior environments store cold goods, house food-processing lines and have a multitude of other uses. When constructing a roof system on a cold-storage facility, workmanship and attention to detail are critical. A tiny air leak that would be of little to no consequence in a roof system on an office building can lead to moisture and/or ice formation on a cold-storage facility, as well as endless service calls from the facility owner.

Understanding special details and tolerances required for cold-storage facilities can help when designing and constructing roof systems to meet these challenges, which become greater the colder the interior environment.

Overall design approach

Refrigerated environments (coolers) range from above 32 F to below -10 F for deep freezers, and in some cases, blast freezers can approach -50 F for interior temperatures. There are three basic design approaches for cold-storage facilities.

The first method is to build the envelope for the cold environment within the standard building envelope. This is the most expensive method but leads to the greatest chance for success. Also known as the nested approach, conceptually similar to a Russian nesting doll, this technique is seen at grocery stores, convenience stores and even your home with a refrigerator-freezer. This concept can be scaled up to hundreds of thousands of square feet for large commercial food distribution for grocery chains. In these distribution centers, dry, refrigerated and frozen goods are housed in one building up to and well beyond 1 million square feet. One of the many benefits to this approach is the roof system requires no particularly special techniques or details. Repairs and reroofing also are substantially easier.

The second and most common technique is to construct the building envelope as the exterior envelope of the cold-interior environment facility. The walls of this type of construction typically are made from insulated metal panels and provide challenges in roof edge detailing, but careful workmanship can make this design approach a successful one.

The third approach involves converting an existing building into a cold interior environment facility. Typically, the owner will buy and repurpose an existing building by converting the interior to cold storage. As with anything in construction, with enough money and planning anything can be accomplished. However, adding insulation to the walls and roof and then bringing in refrigeration equipment does not address all the considerations that go into a trouble-free refrigerated space, let alone deep-freeze buildings. I recommend avoiding these types of roofing projects because when they fail, they do so spectacularly.

Moisture flow and vapor retarders

In cold-storage facilities, moisture vapor flow is reversed from a traditional building in a northern climate, including the roof. In this situation, the water vapor on the outside of the building will, by vapor pressure differential, move into the cold-storage building’s interior.

To prevent moisture from getting in and condensing, a vapor retarder needs to be placed on the building envelope’s exterior. Fortunately, roof membranes almost always are great vapor retarders. But in a cold-interior environment facility, the roof membrane is on the warm exterior side. So a vapor retarder in its typical position on the roof deck is of little value and can, and does, cause problems in cold-interior environment facility roof system designs.

Many products used in roof systems have varying water vapor retarding capabilities (perm ratings). When moving from the exterior to the interior of a cold-storage facility, various layers of vapor-retarding capability are used. Each successive interior layer should have a higher perm rating than the previous layer. The ideal amount of perm rating changes per vapor-retarding layer and is around an order of magnitude (i.e., 0.01 perm to 0.1 perm or 0.1 perm to 1.0 perm).

For example, if we use a 60-mil-thick TPO membrane (about 0.08 perm) for the roof membrane and the next major vapor-retarding layer is a metal roof deck (about 1 perm), the design should work. However, if we use the same 60-mil-thick TPO membrane (about 0.08 perm) for the roof membrane and put a 6-mil-thick polyethylene film (about 0.06 perm) on the metal deck, we can create a possibility for moisture accumulation. This moisture accumulation can become ice in facilities colder than 32 F.

Air seals

Moisture issues directly attributable to water-vapor diffusion are rare. Air leakage (advection) causes a vast majority of problems in cold-storage facilities. During advection, warm, moisture-laden air from the building exterior leaks into the roof and beyond, depositing moisture on any surfaces below the air’s dew point. A major part of the design and installation of cold-storage facilities should be preventing air movement between differing sections of the building and between the interior and exterior.

Within the building footprint, air needs to be stopped from moving between areas of the building that are different temperatures. Examples include refrigerated space to freezer space, office space to refrigerated space and particularly from loading dock to adjacent cooled spaces even if the loading dock itself is cooled. Even well-sealed loading dock doors can allow warm, moist exterior air to enter a facility in copious amounts. Warm air rises by thermal buoyancy, and moist air rises by hygric buoyancy; both factors will cause air to enter and rise to the underside of the roof deck. Once on the underside of the roof deck, this air can travel by HVAC-driven air pressure. The hats and flutes of a metal roof deck make great air-flow channels between interior spaces of a building.

Photo 1: A field installation of an air-stop detail between a loading dock at 55 F and a food-production area at 36 F. Note the deck flutes are filled solid and the membrane has been dropped to the deck to prevent air movement between the areas.

Photo 1: A field installation of an air-stop detail between a loading dock at 55 F and a food-production area at 36 F. Note the deck flutes are filled solid and the membrane has been dropped to the deck to prevent air movement between the areas.

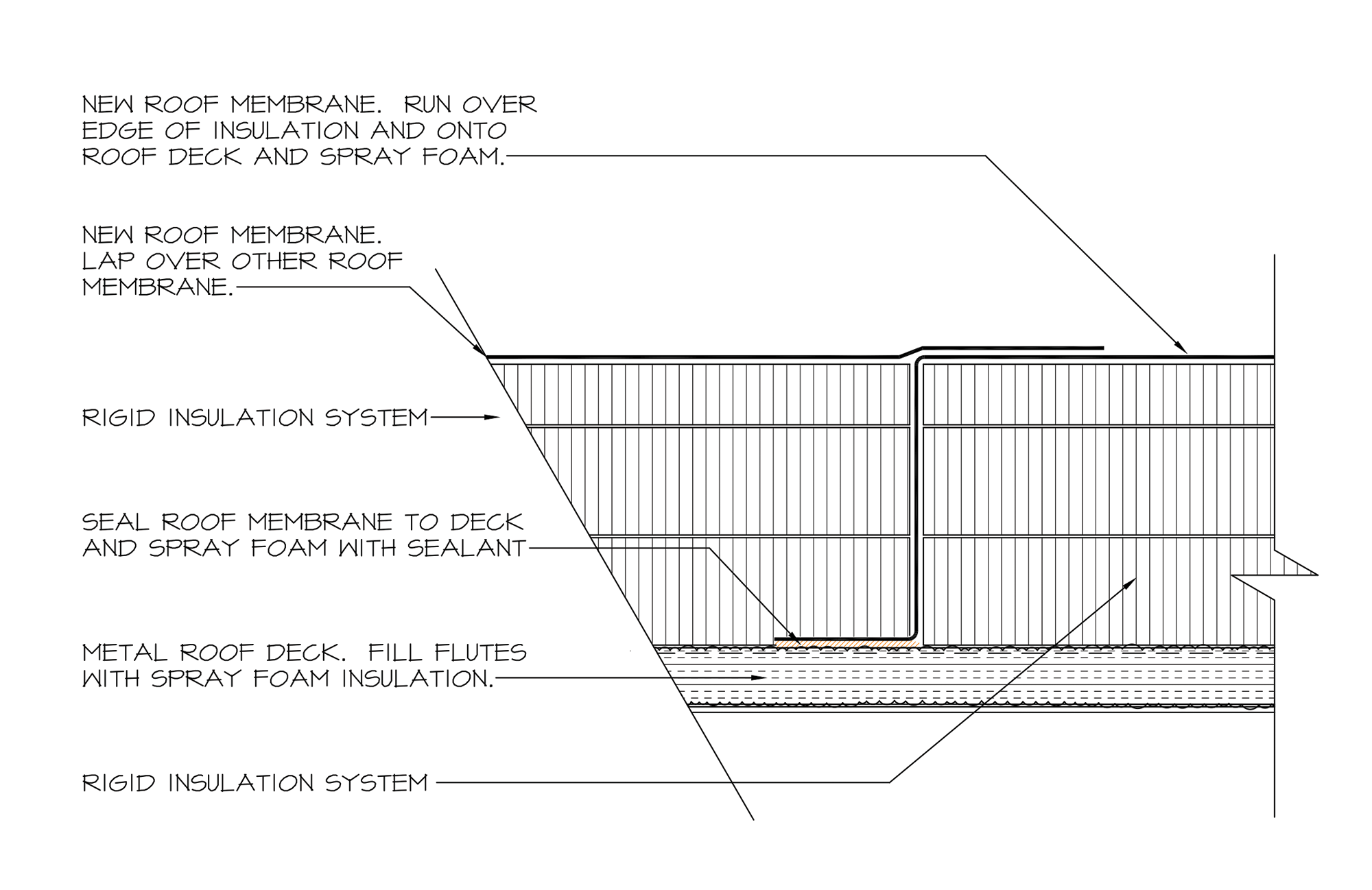

The metal roof deck and everything underneath it typically are the responsibility of another trade. But when constructing a roof system, you can do some things to make it as resistant to air flow as possible. In the detail in Photo 1, there is a change between the refrigerated loading dock and refrigerated production area. The air-seal detailing includes:

- Premanufactured polyethylene foam closure strips set in butyl sealant within the metal deck flutes

- Closed-cell spray foam applied and then trimmed flush in the deck flutes to both sides of the dividing wall—typically 1 to 4 feet to either side of a wall where the temperature changes

- The single-ply roof membrane brought down to the metal deck and set in butyl sealant, along with the insulation boards, providing the mechanical restraint to keep the membrane on the deck in place along with the butyl

- The membrane continued over the top and heat-welded

Using closed-cell spray foam in the metal deck flutes is invaluable in this and other areas of a roof to keep air in its intended place. Figure 1 shows a CAD cross-section of this air-stop detail.

Figure 1: A detail of a roof system air-stop detail

Figure 1: A detail of a roof system air-stop detail

Any time there is a penetration through the deck, such as a roof drain, refrigeration pipe, plumbing vent, expansion joint or mechanical penthouse, spray foam should be applied to the metal deck flutes for the same 1 to 4 feet at a temperature change. In places where metal deck has been cut for penetrations to pass through, such as a plumbing vent, the hole should be completely filled with spray foam around the penetration, providing a solid air seal. All this prevents the roof from becoming an air conduit and leading to condensation or ice issues.

It is important also to address concrete decks over cold interior environment facilities. Concrete decks lack flutes to pass air. However, a common design choice is to use low-rise foam adhesives to assemble the roof system. But in this case the foam ribbons can act as air channels within the layers of the roof. To prevent this, use full ribbons of foam applied across a newly laid board, along with the standing “S” foam pattern as called for in wind design, which provides air cutoffs. The same guidance applies to concrete decks and metal decks where all penetrations through the decks need to be sealed airtight with spray foam.

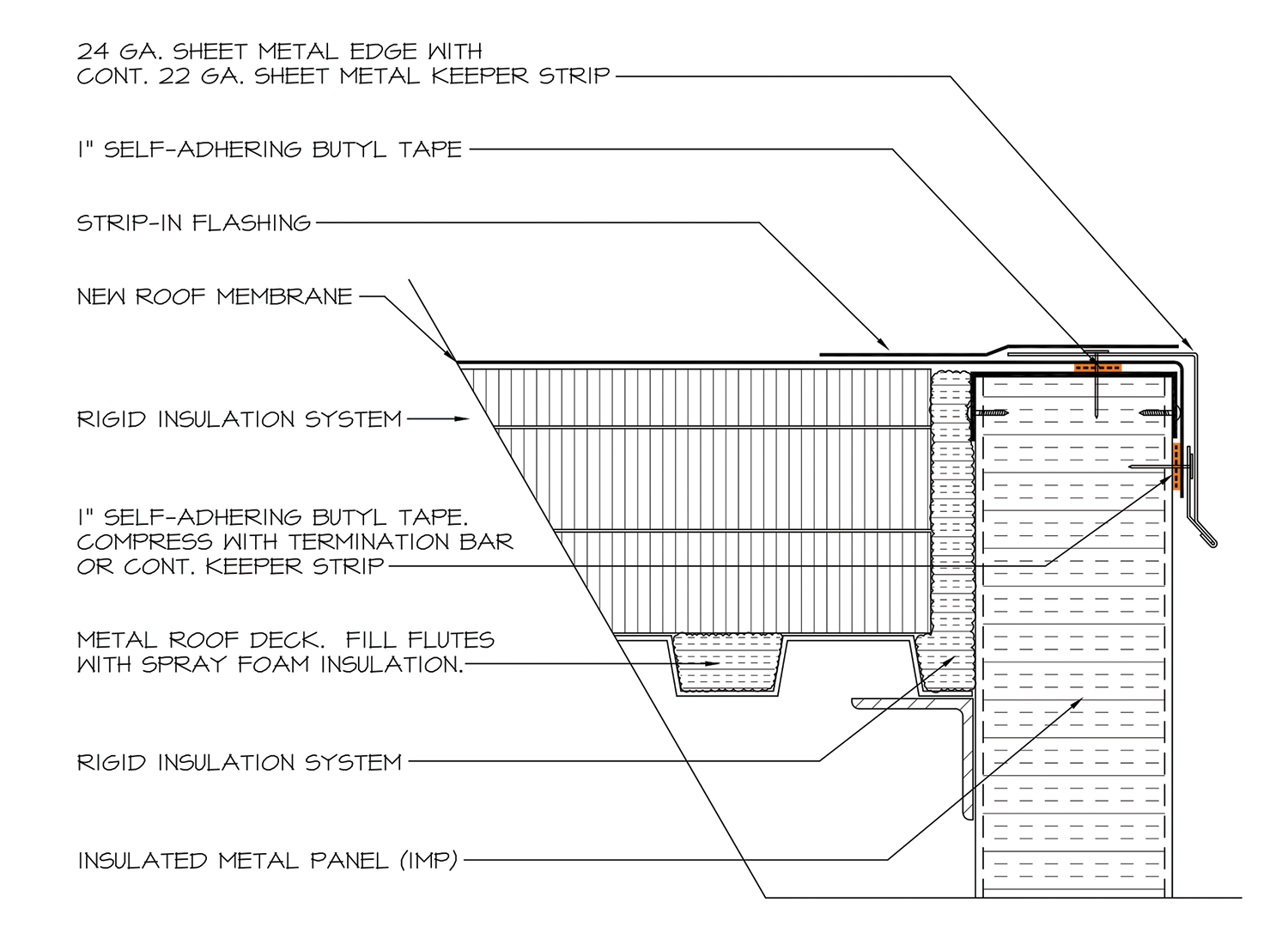

Regardless of roof deck type, another critical place for air-seal details is at the roof edge. Whether it is a parapet, gravel stop, gutter or something in between, they all need air-seal details for the roof system to function satisfactorily. The exterior air seal should be redundant (more than one seal) so if one of the seals fails over time or by workmanship, there is a backup. Typically, this means one seal on the exterior face of the wall and one seal on top of the wall. The more difficult place to make this air seal is on the outside face. When the building exterior typically is composed of insulated metal panels, it will be a corrugated profile with a galvanized-steel cap on the wall. Both scenarios make detailing difficult.

Figure 2: An edge air-stop detail

Figure 2: An edge air-stop detail

To make a seal using a single-ply membrane, use 3/4- to 1-inch-wide self-adhering butyl tape. Apply the tape continuously, butting the end of the roll tight to the next roll. On the outside face of the wall, use a termination bar or metal cleat on the membrane by passing the fasteners through the butyl tape underneath, creating a field-fabricated compression seal. The seal on top of the wall should be compressed by any edge metal used. If mechanical fastening is used on top of the wall, use the butyl strip in the same location to make a redundant compression seal.

In addition to the air seal at membrane level, use spray foam in the metal deck flutes at exterior walls. Further, the gap between any board insulation and cover boards at the outside wall should be foamed solid. Photos 2, 3 and 4 show the foaming and sealing that needs to happen at outside walls. Figure 2 shows a CAD cross-section of this air-stop detail.

Photo 2: A view of field-installed spray foam at a roof perimeter. The worker is using a long nonserrated blade in the reciprocating saw to trim the foam flush—a laborious but necessary step.

Photo 2: A view of field-installed spray foam at a roof perimeter. The worker is using a long nonserrated blade in the reciprocating saw to trim the foam flush—a laborious but necessary step.

Photo 3: A view of a roof perimeter near completion. Note the spray foam at the roof edge between the insulated metal panel wall and the insulation and cover board, sealing against air movement. Additionally, a strip of butyl with its release paper still in place is installed and ready at the outside edge of the galvanized insulated metal panel wall cap.

Photo 3: A view of a roof perimeter near completion. Note the spray foam at the roof edge between the insulated metal panel wall and the insulation and cover board, sealing against air movement. Additionally, a strip of butyl with its release paper still in place is installed and ready at the outside edge of the galvanized insulated metal panel wall cap.

Photo 4: A view of a worker removing the release paper from a butyl strip on the exterior face of an insulated metal panel wall. This is the primary air seal. After the membrane is flopped over the wall, a heavy-gauge metal cleat will be fastened through this butyl strip. This will provide a compression seal as well as the cleat for the edge metal. Also visible is a white butyl-based sealant that was applied to the gap in the galvanized insulated metal panel wall cap.

Photo 4: A view of a worker removing the release paper from a butyl strip on the exterior face of an insulated metal panel wall. This is the primary air seal. After the membrane is flopped over the wall, a heavy-gauge metal cleat will be fastened through this butyl strip. This will provide a compression seal as well as the cleat for the edge metal. Also visible is a white butyl-based sealant that was applied to the gap in the galvanized insulated metal panel wall cap.

Insulation

Using larger-than-normal amounts of roof system insulation in cold interior environment facilities should be expected. The decades-old fight of R-value per inch of insulation against cost is not in debate here. All forms of insulation, including polyisocyanurate, extruded polystyrene, expanded polystyrene and mineral wool, have been used on cold-storage facilities. When manufactured, designed and installed correctly, any of these insulation types will perform satisfactorily.

There are two things to keep in mind with insulation on cold-storage facilities. The first is design. When designing for energy usage and HVAC equipment sizing, metal fasteners that pass through insulation can lead to energy loss as addressed in ASTM International’s Roofing Research and Standards Development: 8th Volume and other studies. One way to minimize this in most buildings is to mechanically fasten the first layer of insulation and adhere the remaining layers of insulation.

The second issue involves installing the insulation and the inevitable gaps in the insulation board joints. Ideally, a perfect installation would have no gaps anywhere. Although this is ideal, it is not the reality of roof system installation. A gap is not terminal for a cold-storage interior environment facility, but an installer needs to be mindful of these gaps. When gaps occur, they should be filled with the same spray foam used in the metal roof deck flutes, penetrations and perimeter walls. A rule of thumb for this application is any gap larger than 1/8 of an inch should be filled. The thicker the insulation boards, the more critical it is to implement this quality control technique.

Membrane attachment methods

The roofing industry has a mind-boggling amount of roof systems available. Only a small number of about 1 million unique roof systems listed in FM Approvals’ RoofNav® may be suitable on cold-storage facilities.

Generally, two categories of roof systems are most commonly used on cold-storage facilities. With concrete roof decks, an adhered system is the most common choice. Asphalt as an adhesive or low-rise foam adhesive also are routinely used with success.

Steel roof decks are more commonly seen on cold-storage facilities where induction-welded thermoplastic single-ply membranes are popular and have performed well. However, beware of in-seam mechanically fastened systems. As presented in “Condensation Risk of Mechanically Attached Roof Systems in Cold-Climate Zones” from the 28th RCI (now International Institute of Building Enclosure Consultants) International Convention and Trade Show proceedings, in-seam systems have a high propensity to induce air movement that causes condensation issues. Therefore, in-seam mechanically fastened single-ply membrane roof systems are not a recommended choice on cold-storage facilities.

Historically, ballasted roof systems have been a popular choice for cold-storage facilities. Currently, ballasted roof systems often are restricted by wind provisions in building codes. Although a ballasted roof system still is a possibility for cold-storage facilities, caution is advised as the loose-laid insulation in a ballasted roof system can lead to large gaps from long-term movement of the unrestrained insulation. As previously discussed, large gaps generally are problematic for air movement.

Reroofing and remediation

Working on the roof of a nested building envelope typically is not a major issue as the cold environment and its special envelope are inside the building. Reroofing, modifying and repairing the roof system are possible without additional precautions.

However, when reroofing or making an in-depth remediation of a roof system over a cold roof deck, condensation problems can occur.

If the cold-storage facility is still active, an exposed roof deck will quickly condensate and/or frost. Unless you operate in northern climates and are working during wintertime, the interior temperature most likely is at or well below the dew point or even freezing point. Work should be delayed until the outdoor temperatures are suitable enough for the metal deck to be above the dew point of outside air conditions. The materials available and speed at which the roofing crew can work is limited at these temperatures. But if the interior cooling system will not be turned off, these are the reroofing and remediation conditions in which a roofing contractor needs to work.

Given these difficulties in reroofing or even repairing a roof over a cold-storage building, the owners of these facilities need to be well-versed in the conditions of their roof systems and the timelines for reroofing when the roof is part of a cold-storage envelope.

Don’t get caught in the cold

Designing, selecting and installing materials for roof systems on cold-storage facilities can be successfully accomplished with proper research, detailing and quality control. Air flow within the building envelope of cold-storage facilities is critical and must be controlled at roof penetrations, temperature change boundaries and exterior walls. Following these recommendations can dramatically improve the performance of cold-storage facility roof systems.

Matt Dupuis, PH.D., P.E., is a principal with SRI Consultants, Middleton, Wis.