The small, common stones used as roof ballast possess few individual attributes worthy of extensive examination. But the combined effect of these small stones has been gigantic within the roofing industry.

Ballast enables roofing crews to install large sheets of roof membrane quickly and efficiently in a wide range of weather and temperature conditions. And ballast enables underlying roof membranes to accommodate structural building movement and allows for the direct application of highly efficient thermal insulation boards that might otherwise need to be protected from roofing asphalt or adhesives.

Because of these unique features, hundreds of millions of square feet of ballasted roof systems have been installed throughout North America for nearly three decades. Assuming a service life of 15 to 20 years, it is reasonable to project that nearly 10 billion square feet of ballasted roof systems are currently in service.

Consider what as little as 10 pounds of ballast stone placed on a loose-laid roof membrane can accomplish. If you were to test a roof membrane covered with ballast on a wind-uplift pressure table, the ballast stones would be quickly displaced by the expanding membrane, causing almost immediate roof system failure. But in the field, ballasted roof systems have withstood wind speeds up to 100 mph and equivalent uplift pressures in excess of 45 pounds per square foot.

How can 10 pounds of small stones accomplish something that experimental data and common sense would seem to indicate should require 50 pounds or more? The answer is there are other less apparent physical forces at work beyond the stones' individual weights.

It took the roofing industry some time to fully understand these unusual forces. It required extensive wind tunnel research to determine that roof ballast is much more affected by horizontal wind than vertical uplift. And it took years of field study to document that thousands of individual stones loosely laid over roof membranes work together to dissipate uplift pressures over large areas of a roof. Currently, roof ballast's wind-resistance properties are understood and standardized just as other basic engineering principles.

Green ballast

Similar to how ballasted roof systems have helped transform the roofing industry during the past 30 years, they may play an equally important role in meeting the challenges of the emerging green building movement. With its emphasis on energy efficiency and environmental responsibility, green building design places a premium on a construction material's capability to minimize its energy use and environmental footprint.

And just as ballast's unusual properties allowed it to previously transform the roofing industry, there appear to be even more overlooked properties of ballast that may enable it to be an important change agent in green building design and construction.

Cool ballast

Although stone ballast has a relatively low thermal resistance, or R-value, the combined mass of stones and the air spaces within the ballast matrix act as an effective insulator against the intrusion of solar heat energy into a building. This principle of thermal mass has been used to keep buildings cool for centuries, the thick adobe buildings of the Southwest being a leading example. And similar to adobe, roof ballast's energy-saving benefits are greatest during the critical hours of the late afternoon when electrical demand for cooling peaks.

Scientific research has begun to quantify these energy savings, and a ballasted roof system's beneficial effects on building cooling loads appear significant. According to a four-year study conducted by Oak Ridge National Laboratory (ORNL), Oak Ridge, Tenn., the overall interior heat load, or flux, generated by a ballasted roof system with 17 pounds of stone per square foot is virtually identical to the heat load of a "cool" reflective membrane roof system with 65 percent surface reflectivity.

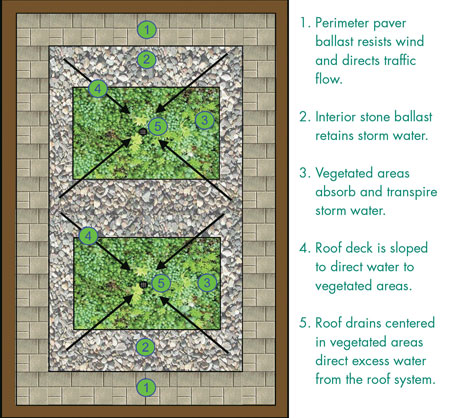

Figure courtesy of TEGNOS™ Research Inc., Carmel, Ind.

An example of a hybrid ballasted and landscaped roof system

Extrapolation from this comparison suggests that even ballasted roof systems with the minimum weight of stones of 10 to 12 pounds per square foot could enable a reflective roof system to meet the current ENERGY STAR® minimum reflectivity requirement of 50 percent.

Similar to its low R-value, stone ballast's nominal solar reflectivity also is relatively low, usually less than 20 percent. But just as R-value doesn't predict ballast's energy savings, research suggests ballast's low nominal reflectivity likewise leads to underestimation of its value in reducing radiated heat flow to the atmosphere.

In the same ORNL study, the surface temperatures of ballasted roof systems—and thus their contribution to the widely reported "urban heat island effect"—were virtually identical to the surface temperatures of cool, reflective roof systems. In fact, some ballasted roof systems performed better than the reflective roof systems in reducing the urban heat island effect by delaying their temperature peak until several hours later in the day, thus reducing peak afternoon heating effects.

Based on these results, ORNL researchers concluded ballasted roof systems should be considered equal to current cool roof systems as rated and defined by the ENERGY STAR program and Title 24 of the California Energy Code. And as a result of the ORNL study and other research, ballasted roof systems' energy-saving and heat island-reducing capabilities are starting to be recognized.

At press time, inclusion of some ballasted roof systems as equivalent "cool" roofs appears to be a certainty in the 2008 edition of California Title 24, and the American Society of Heating, Refrigerating and Air-Conditioning Engineers Inc. appears to be seriously considering ballast's inclusion as a cool roofing alternative.

The perfect partner

Many cool roofing standards, including Title 24, ENERGY STAR, and the Leadership in Energy and Environmental Design® Green Building Rating System,™ consider landscaped roof systems, or roofs covered with living vegetation, to be an alternative equivalent to cool reflective roof systems.

Based on the research previously discussed, it appears ballasted roof systems should share this cool roof designation. However, ballasted and landscaped roof systems share an additional environmental benefit not usually associated with reflective roof membranes: Both ballast and vegetation may be used to collect and reduce storm water runoff.

Of course, landscaped roof systems do more than merely slow down storm water runoff. Landscaped roof systems actually use the water to grow plants that eventually transpire the water to the atmosphere. Unfortunately, these added water-retention benefits come with a significant cost—a square foot of a landscaped roof system can cost many times the unit price of ballasted or other conventional roof system types.

Because of the relatively high premium for landscaped roof systems, the use of "hybrid" roof systems consisting of well-designed combinations of ballast and vegetation may help stimulate increased demand for landscaped roof systems by reducing their overall cost per square foot. By locating roof drains directly beneath a roof's landscaped portions and surrounding those areas with stone ballast, excess storm water could be retained within the roof's ballasted portions until the water could be used within the landscaped areas.

In addition, if ballasted areas were located around a roof's perimeter, the ballasted portions could be designed to accommodate high wind speeds, which may be important in meeting building code requirements on many tall urban buildings.

As an example, the ANSI/SPRI RP-4 Wind Design Standard for Ballasted Single-ply Roofing Systems as adopted by the International Building Code provides criteria for the use of ballasted roof systems on buildings up to 150 feet tall located outside hurricane-prone coastal regions, depending on parapet height and the size and weight of ballast selected.

Finally, if ballasted areas were designed to accommodate and direct rooftop traffic, maintenance could be simplified and human use of the green space could be maximized. The figure shows an example of a hybrid ballasted and landscaped roof system that offers improved wind and traffic resistance, as well as economical supplemental storm water retention.

Actually, many landscaped roof systems are designed and installed in combination with ballasted roof systems. In fact, at least one landscaped roof system manufacturer has expanded its modular plant tray system to include the use of ballast in the trays. But because there has been little public discussion of the potential benefits of this hybrid approach, it is likely the real benefits of such an approach are not yet commonly understood and accepted.

The potential benefit of such a synergy may only be increased with additional research into ballasted roof systems. As an example, research to measure ballast's effect on storm water retention would be useful to architects attempting to minimize or eliminate storm water runoff from a building site.

Transforming life cycle

The simplicity of installing a ballasted roof system may also turn out to be a benefit when the time comes to remove a roof system. Because a ballasted roof system requires few mechanical fasteners to restrain it against wind, a roof membrane can be easily removed for recycling at the end of its service life.

Underlying insulation also is a prime candidate for recycling because the integrity of insulation boards in a ballasted roof system is not compromised by through-fasteners or adhesives. And because the useful service life of a well-designed and maintained ballasted roof system may be as long as many other roof system types, its low initial cost combined with the ease of removal and recycling may favorably affect a long-term life cycle.

Early industry recycling initiatives already point to a sustainable and renewable future for ballasted roof systems. In 2007, more than 1 million square feet of ballasted roof systems were recycled in a trial program sponsored by the EPDM Roofing Association (ERA), and ERA reportedly plans to expand the program this year and beyond. And insulation recycling has already moved beyond the pilot stage with a national program now available to contractors for the loading, hauling and recycling of a variety of roof insulation boards.

It should be noted that ballasted roof systems haven't been alone in recent industry recycling efforts. In fact, a number of reflective roof systems also are establishing credible recycling credentials.

Reflective metal roofing naturally lends itself to recycling because a solid network of metal recyclers already covers North America. Several members of the Chemical Fabrics and Film Association's Vinyl Roofing Division have demonstrated that PVC roofing materials also can be successfully recycled in North America as they have been in Europe for many years.

And the successful efforts in recycling PVC roofing materials suggest other reflective thermoplastic membranes, such as TPO, also may be successfully recycled someday. However, as these recycling efforts advance and mature, it is likely ballasted roof systems will remain a prominent focus of recycling activity.

Adding it up

Considering their features and benefits, ballasted roof systems appear ready to take their place as economical and reliable green roofing alternatives.

In areas of the U.S. with high cooling loads and urban heat island concerns, ballasted roof systems offer a reasonable alternative to reflective roof systems. And if used in creative combination with landscaped roof systems, ballasted roof systems may help increase demand for landscaped roof systems by reducing the overall installed cost while maintaining key environmental benefits. Finally, the ease of disassembly of ballasted roof systems may help support a nationwide initiative for a meaningful, effective roofing materials recycling program. Not a bad future for small, common stones!

James L. Hoff, DBA, is research director for the Center for Environmental Innovation in Roofing and president of TEGNOS™ Research Inc., Carmel, Ind.