AceClamp® A2® UL-listed solar kit

|

The A2 clamp was designed specifically for solar applications on standing-seam metal roofs. AceClamp's patented, UL-listed solar kit is the easiest way to install solar panels directly to a standing-seam metal roof. There is no need to waste time or money on a rail system. All clamps and kits are fully assembled. Our patented push-pin design doesn't damage roof panel finishes or coatings and includes a stainless-steel sleeve for grounding. Not only is our clamp universal to many standing-seam metal roofs, but our solar kit is, too, fitting up to a 2 1/2-inch solar panel thickness. For more information, contact us at (860) 351-0686 or visit www.aceclamp.com.

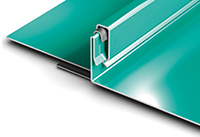

SNAP-CLAD panel: strength and performance

|

Petersen's SNAP-CLAD metal roofing panels feature architectural panel aesthetics and structural panel performance. SNAP-CLAD is corrective-leveled to provide superior flatness. PAC-CLAD® 70 percent PVDF finish is covered by a nonprorated 30-year warranty. It is available in more than 40 colors on steel and aluminum. Most colors meet LEED,® ENERGY STAR® and cool roof certification requirements. For information about Petersen's full product line, visit www.PAC-CLAD.com or call (800) PAC-CLAD.

SnowMax-SB from Alpine SnowGuards

|

ALL NEW! The extremely versatile SnowMax-SB (SnowMax + SimpleBlock) provides a secure attachment point. With two oval-point set screws, the block can be used alone as an attachment device for metal standing-seam roofing applications. An optional clip and bar transform the block into a rugged fence-style snow management system. Increased adjustability and a streamlined design meet and exceed all known building codes. Configurations are available for single- and double-lock seams. For more information, visit www.alpinesnowguards.com, email info@alpinesnowguards.com or call (888) 766-4273.

High-temperature self-adhering underlayment

|

Owens Corning-patented SureNail® Technology is the first and only reinforced nailing zone on the face of shingles. Embedded into every Duration® Series shingle, the tough, engineered woven fabric strip creates a highly durable fastener zone with outstanding gripping power. SureNail delivers a limited warranty for 130-mph wind performance with fewer nails, two times the common bond area of standard shingles and an easy-to-see target area for "no-guess" nailing. For more information, call (800) GET-PINK® or visit www.owenscorning.com/roofing/surenail.

Joint and termination sealant

|

Mule-Hide Products' JTS 1—joint and termination sealant—allows contractors to quickly and easily seal large joints and roof termination bars, including those submerged under ponding water. The 100 percent solids moisture-cured urethane sealant offers excellent workability for dry and wet surface applications with no sagging or shrinkage and minimal odor. Contact Mule-Hide Products at (800) 786-1492 or mulehide@mulehide.com or visit www.mulehide.com for more information.

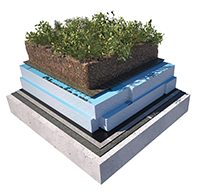

SOPRANATURE vegetative roof systems

|

SOPREMA® Inc.'s SOPRANATURE systems offer semi-intensive, intensive, extensive and modular vegetative roofing solutions. Each system provides the layers required for a successful installation, including a root barrier, drainage and water-retention layers, growing media and pre-grown vegetation. There is a SOPRANATURE system designed for every project type whether it is a simple extensive vegetated roof or an intensive roof garden. Additionally, SOPRANATURE systems are designed for installation over SOPREMA membranes such as SBS polymer-modified bitumen and ALSAN RS PMMA to ensure a finished product with the same quality as all SOPREMA products. Visit www.soprema.us for more information.